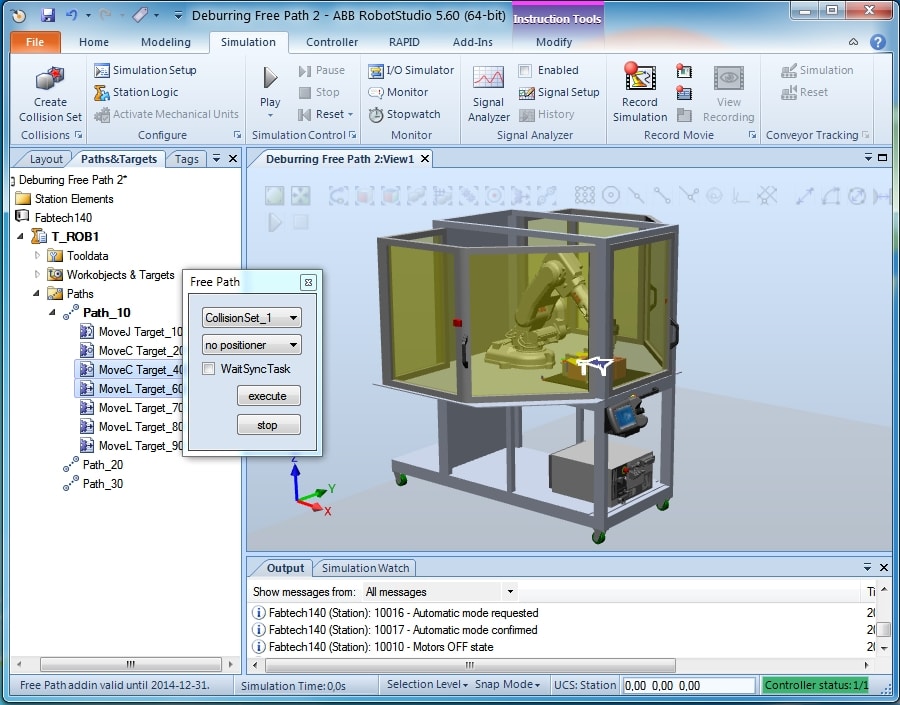

Description

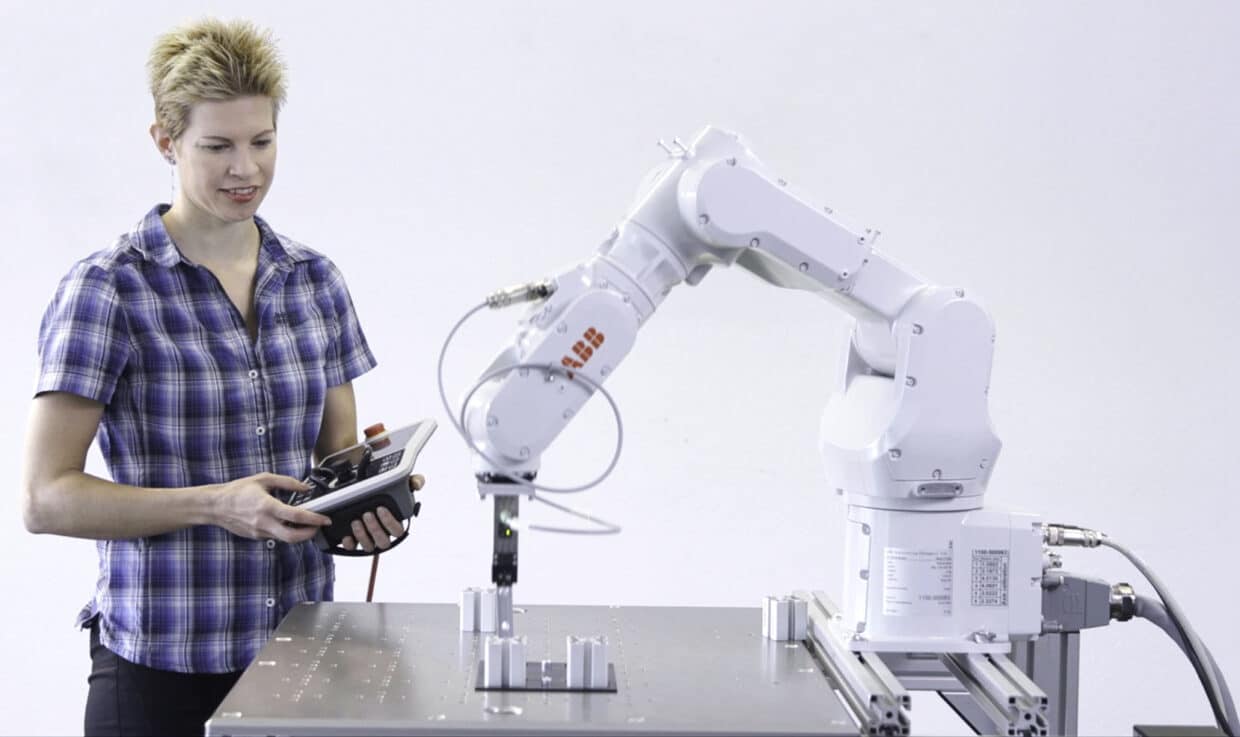

– Compared to the previous generation, the IRB 1100 robot design was optimized with a 10% smaller footprint and over 20% weight reduction for space efficient installation in diverse environments, such as electronics manufacturing factories.

– The small footprint allows multiple robots to be deployed simultaneously in order to collaboratively perform automation operations, enabling more flexible handling for heavy-load operations with complex tools/end effectors.

– Powered by ABB’s new OmniCoreTM controller, IRB 1100 is equipped with advanced motion control capabilities, making it ideal for supporting rapid assembly, pick-and-place, and material handling applications.

– The IRB 1100 has IP40 as standard protection and IP67 as option. The entire robot is designed to be IP67 compliant according to IEC 60529 – from base to wrist, which means that the electrical compartments are sealed against water and solid contaminants.