Description

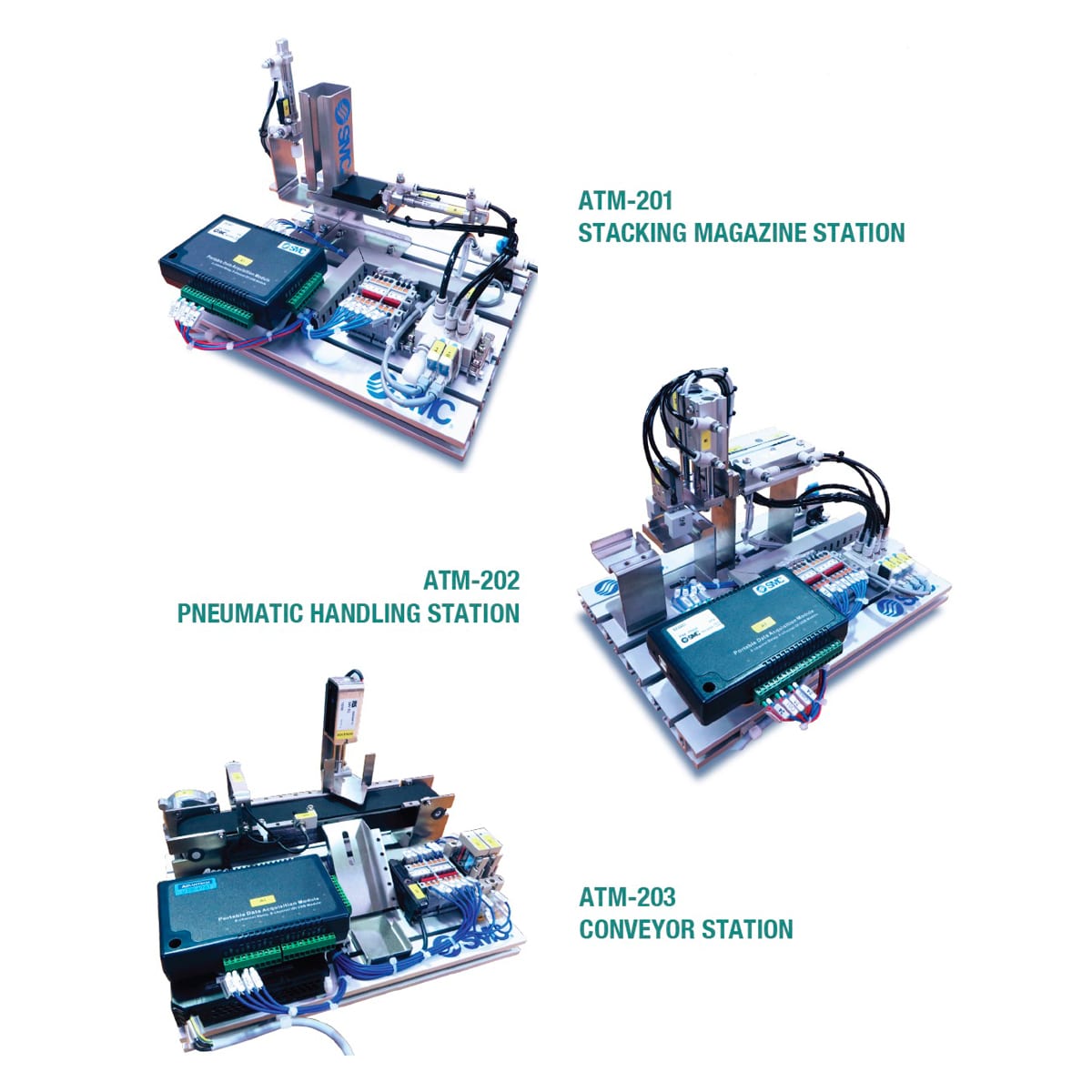

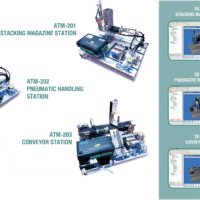

SMC’s ATM-200 is a set of 3 separate training station, fully assembled, built entirely of industrial components.

The set includes a 3D application of each station to simulate and control them from autoSIM-200 environment.

The 3 stations:

- Stacking Magazine Station,

- Pneumatic Handling Station,

- Conveyor Station

are supplied fully assembled in a tabletop anodized aluminum structure.

Each station inputs and outputs are connected to an interface for their control using simulation software on a PC.

- All the stations include autoSIM-200 simulation software (1 license each).

- All the stations include the 3D application for simulate and control the station from autoSIM-200 environment (1 license each).

- Simulate, control and supervise actual automated processes from a virtual environment.

- Include 3D models from the real process.

- Compatible with automation application simulator software autoSIM-200.

- Access to the virtual PLC programming editor integrated in autoSIM-200.

- Access to the table of symbols from the virtual PLC.

- Access to the libraries and to the simulation panel for components in pneumatics, electro-pneumatics, hydraulics, electro-hydraulics and electrics.

- Independent window with 3D model.

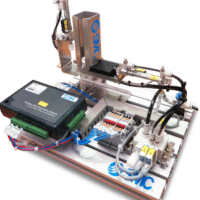

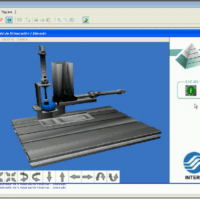

ATM-201: Stacking Station

This first station feeds the piece and verifies its orientation. This operation begins when the start pushbutton of the control and simulation application is pressed.

This module has the following components and characteristics:

-Actuators:

- Horizontal axis: pneumatic cylinder Ø10, stroke: 40 mm, with flow regulators and initial-end position detectors. Controlled by 5/2 way monostable solenoid valve.

- Vertical axis: compact guide pneumatic cylinder Ø10, stroke: 40 mm, with flow regulators and initial-end position detectors. Controlled by 5/2 way monostable solenoid valve.

-Sensors:

- – Reed type magnetic detectors (D-A93L).

Electrical control panel:

- Accessible connection terminals (coded) for power and inputs/outputs.

- I/O station: 4 inputs, 3 outputs.

- Power supply: 24V/26.4W.

- Inputs/outputs interface: data acquisition board for 8 inputs/ 8 outputs with USB connection for PC compatible with autoSIM-200 software (SAI2443).

Software and simulation:

- AutoSIM-200 software (1 license).

- Application for 3D simulation and control of the station from autoSIM-200 environment. (1 license).

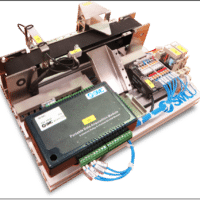

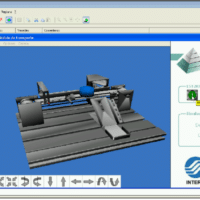

ATM-202: Conveyor Station

This second station moves the pieces thanks to a motorized belt and classifies the pieces thanks to a set of detectors. This operation begins when the start pushbutton of the control and simulation application is pressed.

This module has the following components and characteristics:

– Actuators:

- DC motor, nominal data: 24 V, 7.4 W and 1 Nm torque.

- DC solenoid, nominal data: 24 V, 10 W and 27 mm stroke.

– Sensors:

- Fiber-optic sensor and amplifier.

- Inductive sensor.

Electrical control panel:

- Accessible connection terminals (coded) for power and inputs/outputs.

- I/O station: 2 inputs, 2 outputs.

- 2 relays

- Power supply: 24V/26.4W.

- Inputs/outputs interface: data acquisition board for 8 inputs/ 8 outputs with

- USB connection for PC compatible with autoSIM-200 software (SAI2443).

Software and simulation:

- AutoSIM-200 software (1 license).

- Application for 3D simulation and control of the station from autoSIM-200 environment. (1 license).

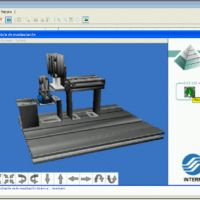

ATM-203: Handling Station

The operation carried out by the third station consists of picking the piece from the initial position (feed position) and placing it on the final position, for this a cartesian manipulator with gripper is used. The piece-manipulation operation requires that there is a piece in the initial position, previously positioned by the user. This operation begins when the start pushbutton of the control and simulation application is pressed.

This module has the following components and characteristics:

– Actuators:

- Horizontal axis: compact guide pneumatic cylinder Ø16, stroke: 50 mm, with flow regulators and initial-end position detectors. Controlled by 5/2 way monostable solenoid valve.

- Vertical axis: compact guide pneumatic cylinder Ø12, stroke: 30 mm, with flow regulators and initial-end position detectors. Controlled by 5/2 way monostable solenoid valve.

- Holding system: Two-finger parallel opening gripper, with miniature fittings. Controlled by 5/2 way monostable solenoid valve.

– Sensors:

- Reed type magnetic detectors (D-A93L).

Electrical control panel:

- Accessible connection terminals (coded) for power and inputs/outputs.

- I/O station: 4 inputs, 3 outputs.

- Power supply: 24V/26.4W.

- Inputs/outputs interface: data acquisition board for 8 inputs/ 8 outputs with USB connection for PC compatible with autoSIM-200 software (SAI2443).

Software and simulation:

- AutoSIM-200 software (1 license).

- Application for 3D simulation and control of the station from autoSIM-200 environment. (1 license).