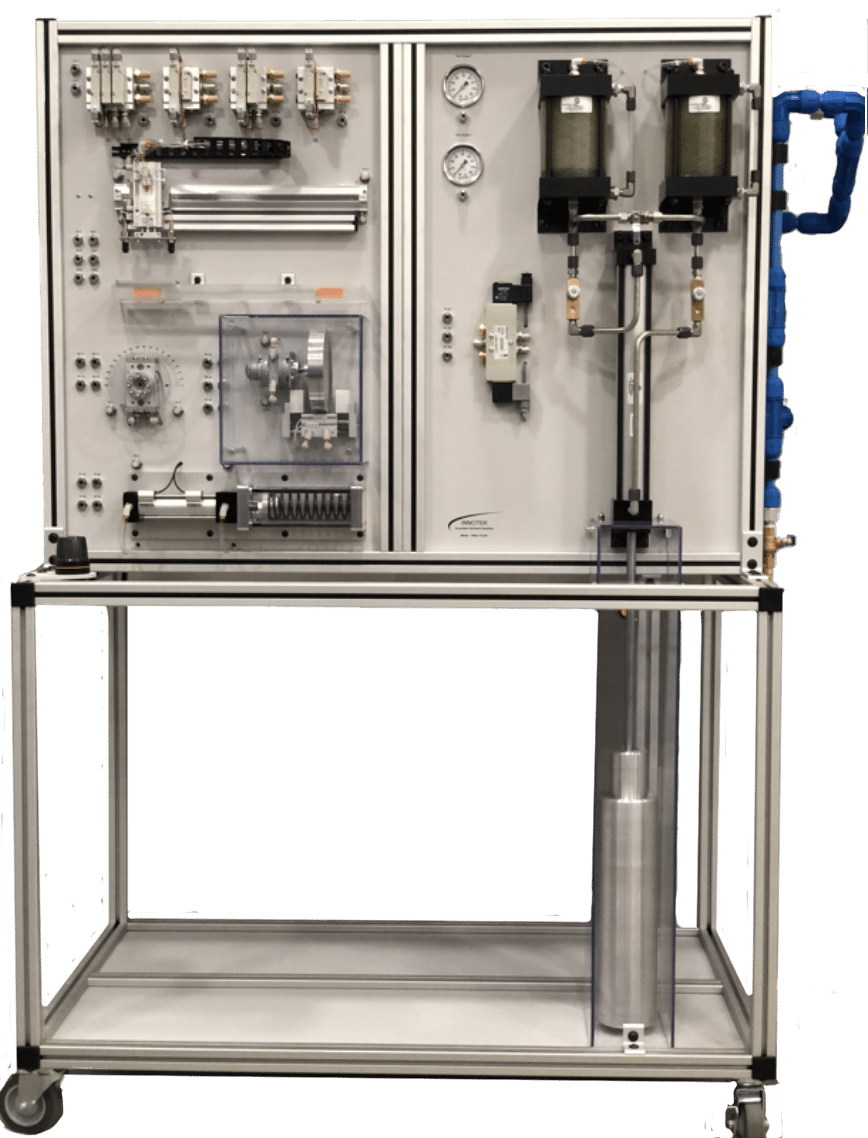

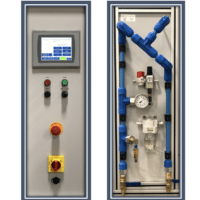

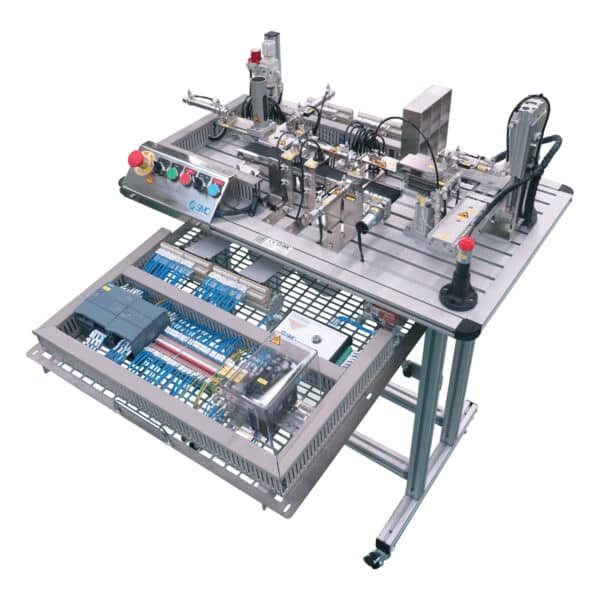

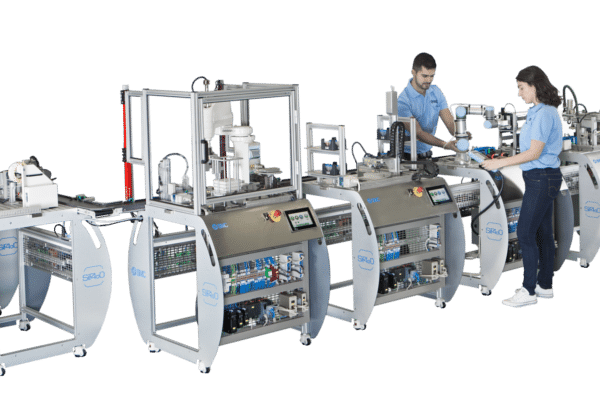

Description

The PNEU-TS-201 Training system provides participants with hardware allowing for hands-on activities in troubleshooting of industrial pneumatic applications. This system gives access to various electrical and pneumatic components which are connected to create six unique applications. The operator control section allows for direct manual and automatic control of each application. Lastly the system includes fault insertion capability to assist in development of a systematic approach to troubleshooting.

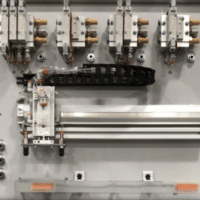

The Pick and Place Manipulator Module

- (1) Rod Less Air/Slide Cylinder

- (1) Double Acting Guided Cylinder

- (4) Actuator Position Sensors

- (1) Vacuum Generator

- (1) Vacuum Switch

- (6) Pneumatic Test Points

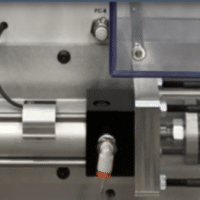

The Loading Actuator Module

- (1) Double Acting Cylinder

- (1) Spring Load Mechanism

- (2) Actuator Position Sensors

- (4) Pneumatic Test Points

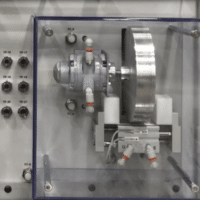

The Rotary Manipulator Module

- (1) Double Acting Rotary Actuator

- (3) Actuator Position Sensors

- (4) Pneumatic Test Points

The Free-Wheeling Motor/Brake Module

- (1) Bi-Directional Air Gear Motor

- (1) Double Acting Clamp Actuator

- (2) Actuator Position Sensors

- (1) Inertial Wheel

- (6) Pneumatic Test Points

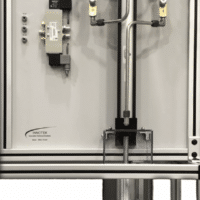

The Air over Oil Application Module

- (1) Pneumatic Directional Control Valve

- (2) Air over Oil Reservoirs

- (1) Equalization Valve

- (1) Double Hydraulic Cylinder

- (2) Hydraulic Flow Control Valves

- (2) Part Detection Proximity Sensors

- (1) Weight Load