Description

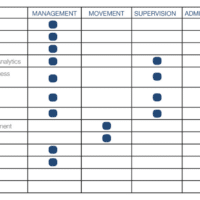

The users, once they have identified themselves, have certain permissions according to the role assigned to them: client, production, maintenance, quality, logistics, plant operator and instructor. The software allows the instructor to create users. Each user is assigned to one role. It is possible to create new roles. It is possible to choose for those new roles which information can be displayed and which buttons can be activated.

Modules:

- Physical Layout: It allows to define the physical layout and the order of the stations for two different PLC brands. The interface is drag and drop style.

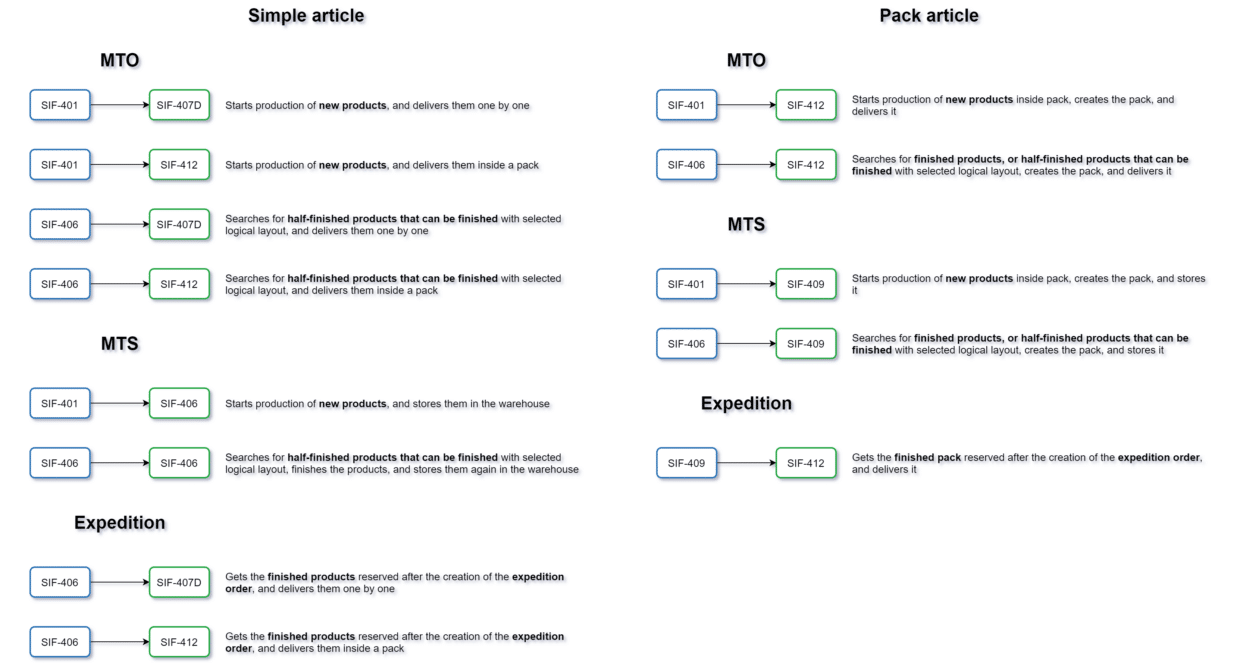

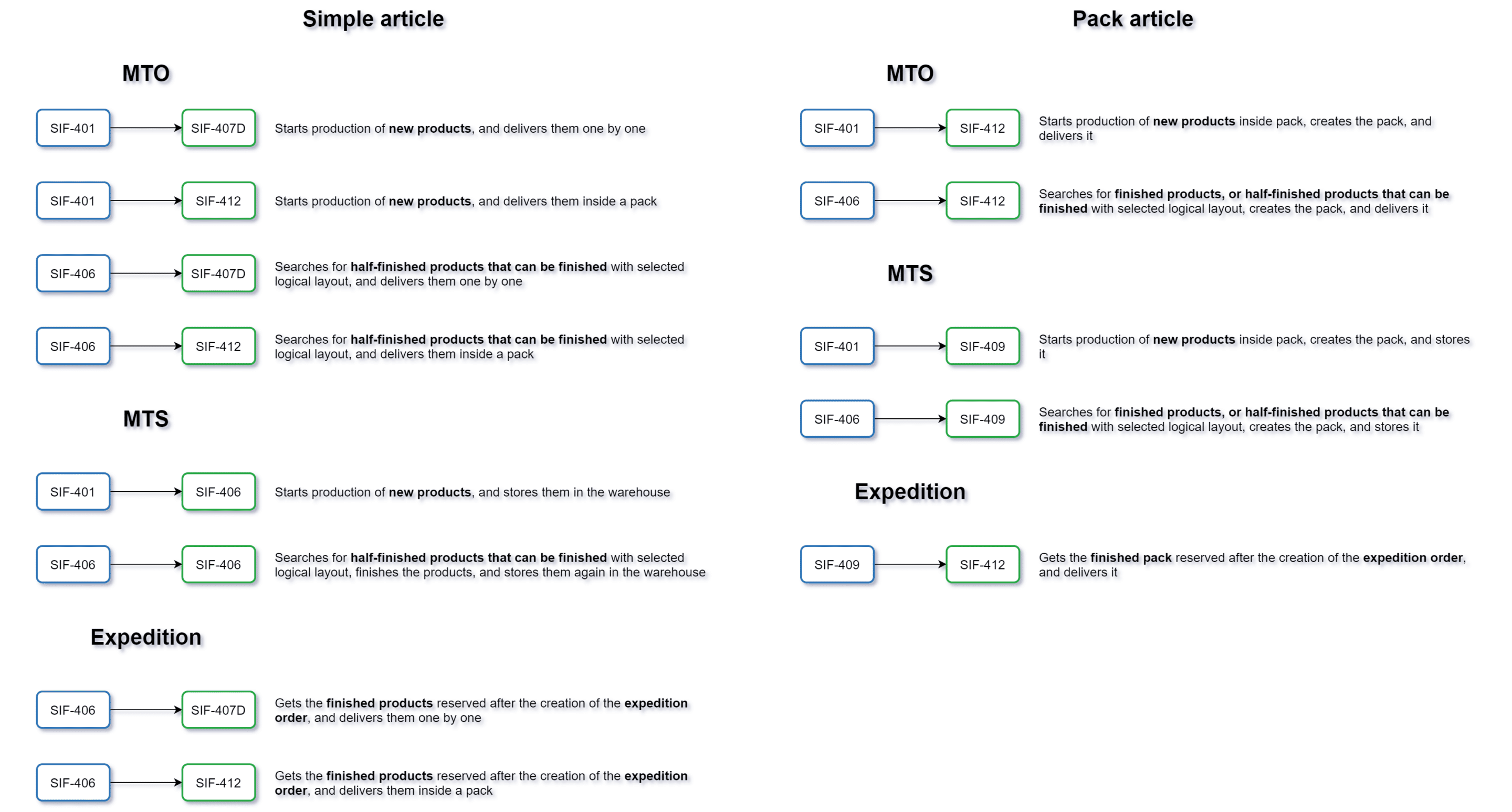

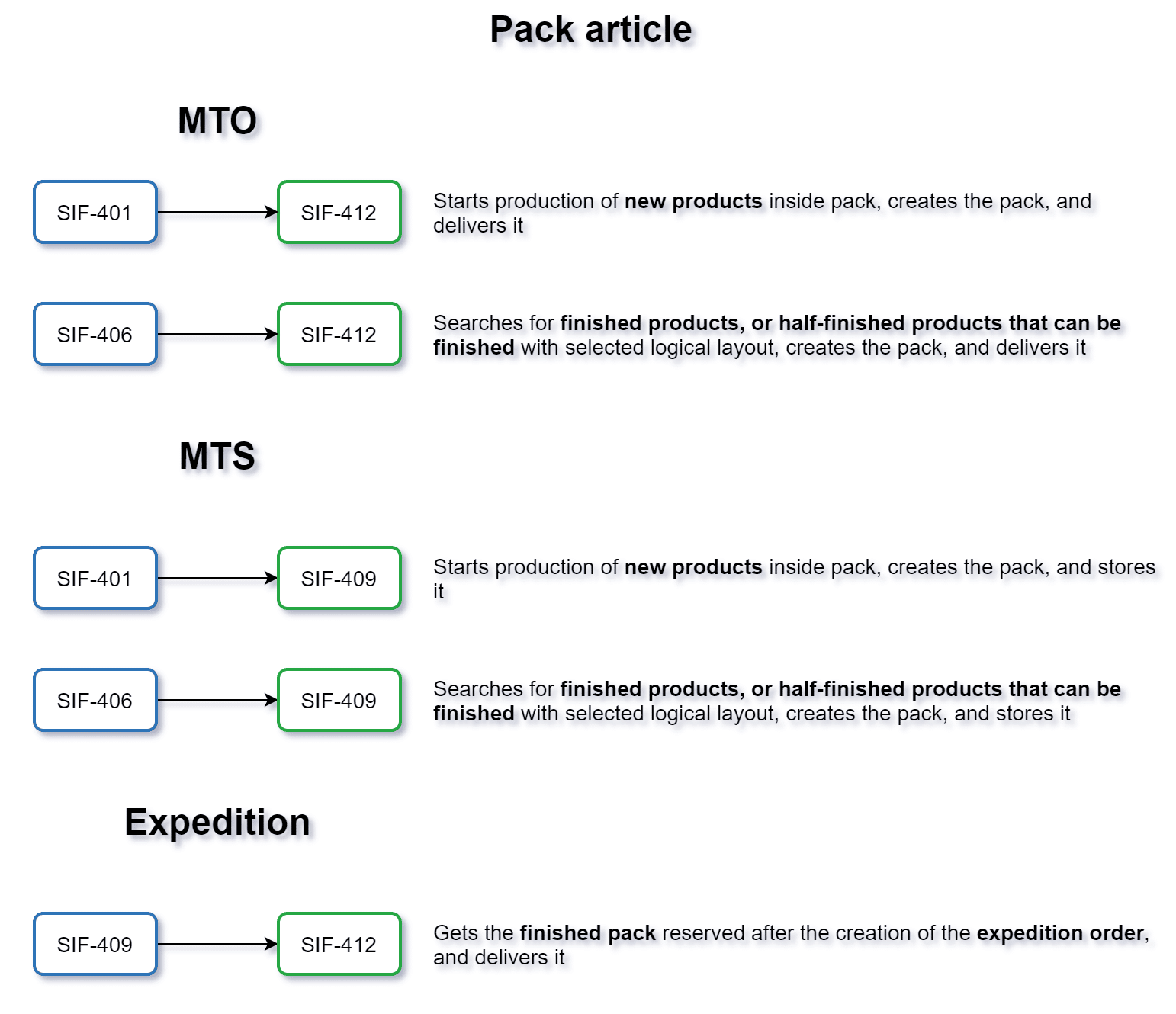

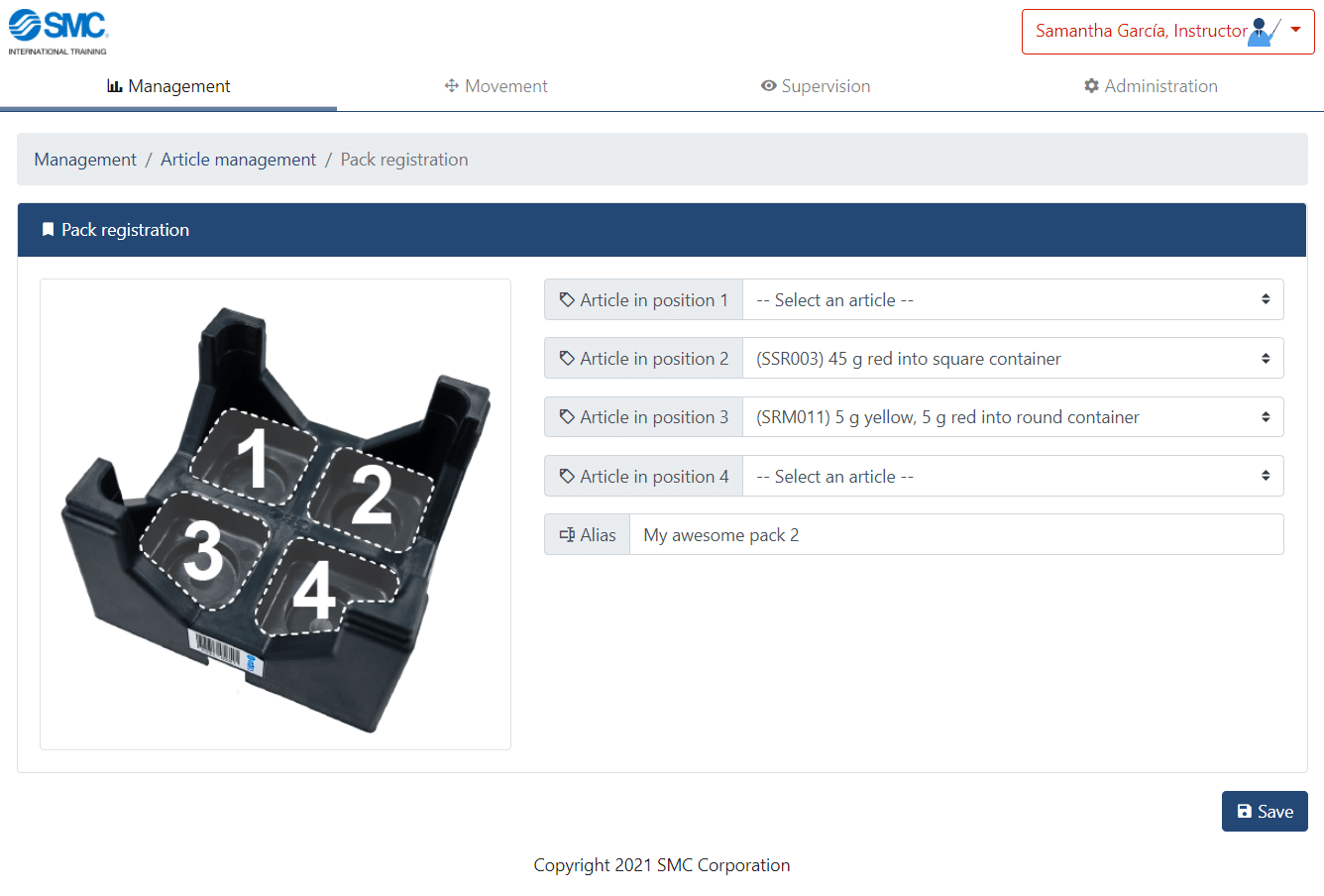

- Logical layout: it allows to create and save logical layouts of three different type of orders: MTS – make to stock orders, MTO – make to order and EO – expedition orders. The interface is drag and drop style. In the logical layout it is allowed OR and AND type logical functions.

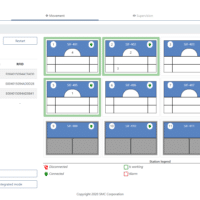

- System status: it allows to see the status of each station. It can monitor when a station is in use or in alarm and it is possible to know if the stations are connected, the work in progress and change the operation mode of the system.

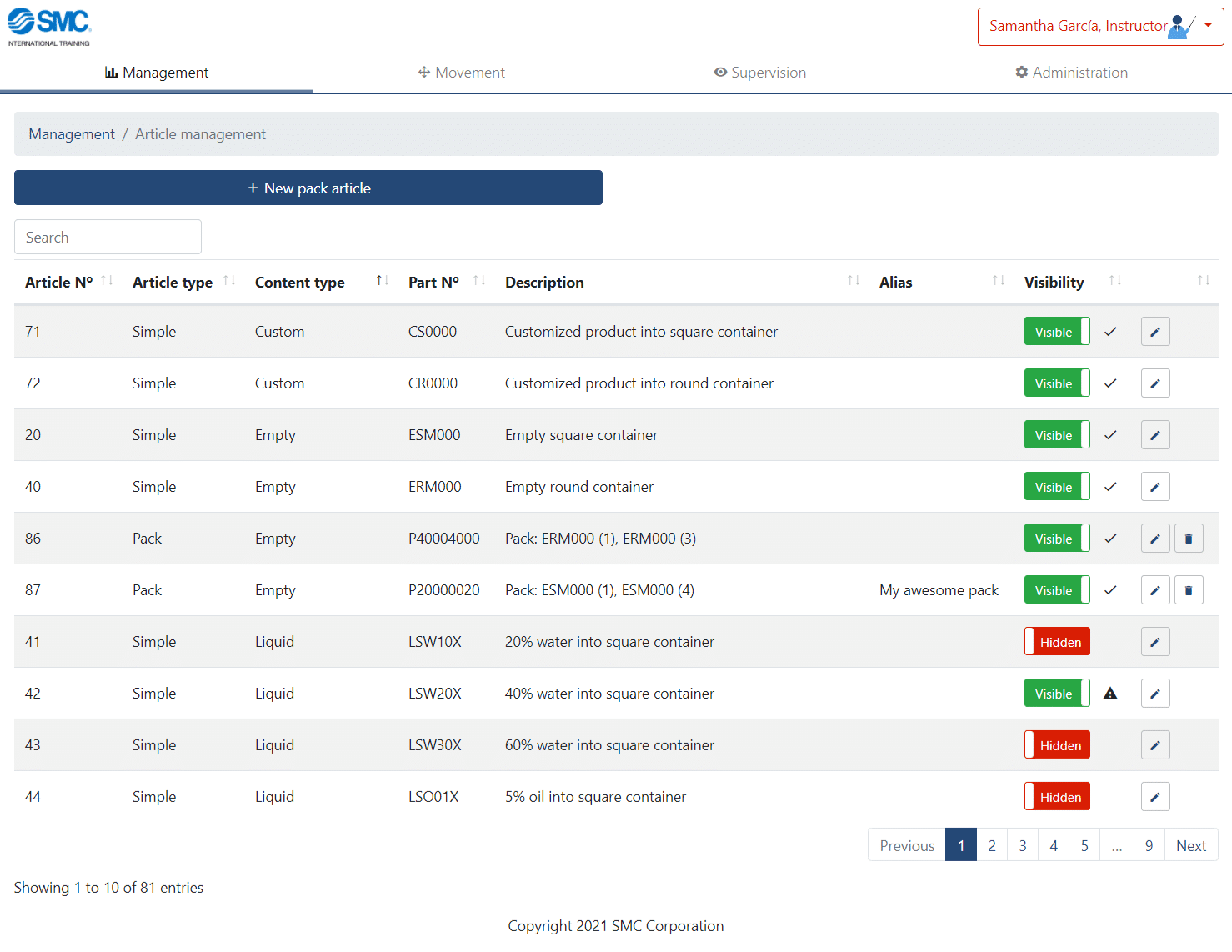

- Customer Management: it allows to create multiple customers and store them in a database.

- Order Management: it allows to record customer orders and stock orders.

- Manufacturing and expedition orders: it allows to create manufacturing orders where user can group different articles from different customer orders before launching them to production. When creating expedition orders, it is possible to check the warehouse status in real time.

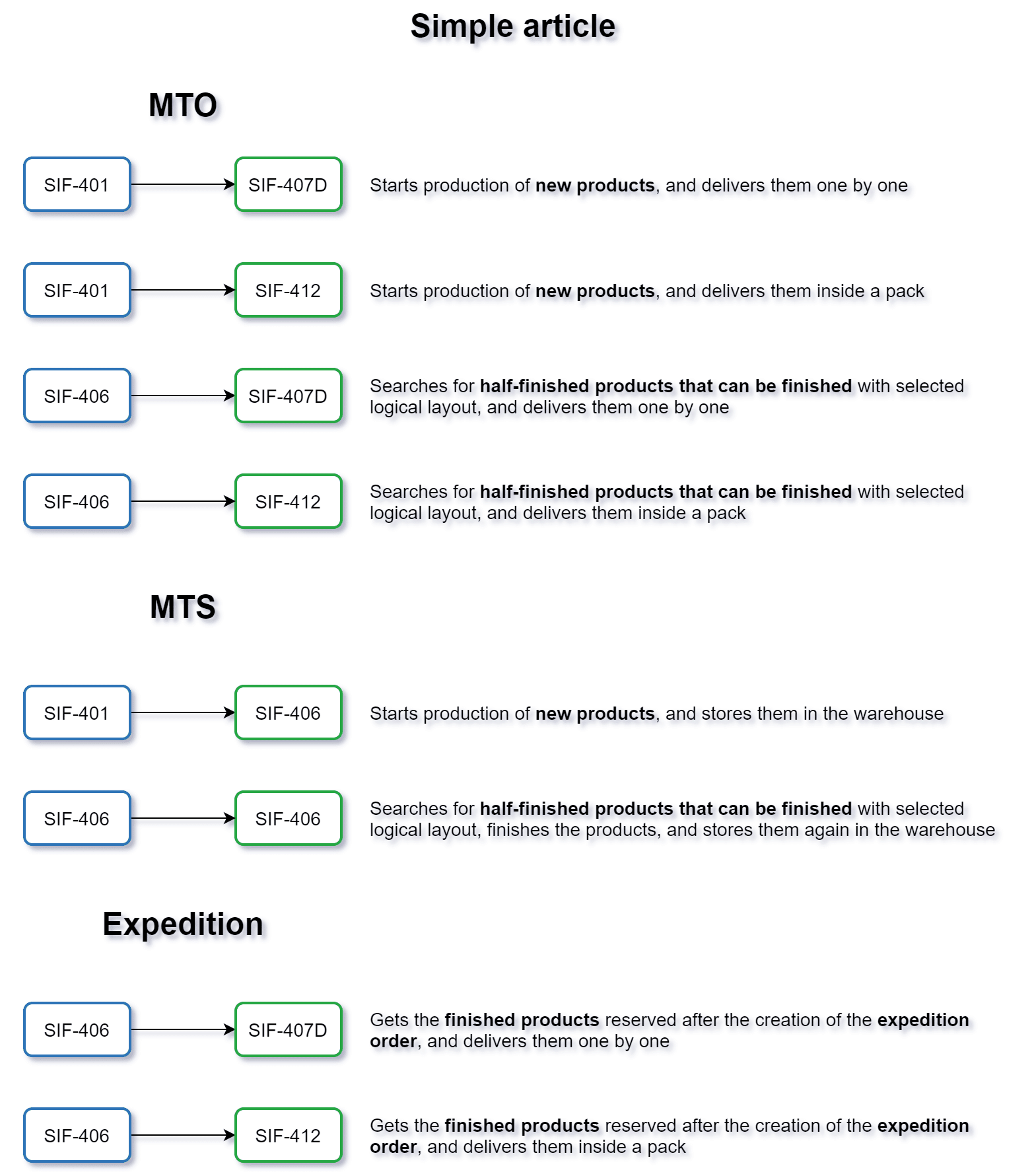

- Dispatcher: it allows to launch production of three different type of orders: MTS – make to stock orders, MTO – make to order and EO – expedition orders. It is possible to select the logical layout to be used during production of such orders.

- Warehouse: it is possible to see the status and the content on each location in the warehouses of the system. It is possible to manage the warehouse with, at least, three different strategies. One of them is variable mode, one of them is according to the article to be stored in each location and another one according to the group of the products to be stored in each location.

- Tracking: it allows to see the progress and the tracking of customer orders, manufacturing and expedition orders and products.

- Maintenance management: It allows to arrange three different maintenance plans in some of the components of the system. One of them is corrective, one of them is preventive and another one is predictive. This last one takes into account, three technics of Machine Learning. It includes a virtual spare parts warehouse and simulated spare parts procurement capability.

- Statistical Process Control: It is based in Sampling Number Statistical Method and generates two X-Bar graphics, one of them for the range of the measured points. It allows to establish upper rejection limit and lower rejection limits.

- Performance Analytics: it includes a general dashboard with four sections of information: OEE, Energy consumption, Quality and Production. Entering in each section it is possible to monitor several Kpis about the topic in each section:

- It is possible to estimate OEE in each station

- It is possible to monitor electrical consumption per station

- It is possible to monitor compressed air consumption for the full system.

Other features:

- The software includes an API for interaction with third party software application.

- It is provided an android app that is connected with management software thanks to the API. This app allows to register the signature of the customer when the product has been delivered. Such signature will be stored and displayed from the management software.