Description

Solenoid-controlled, sub-plate mounted valves are used extensively in industrial plants. They are typically used to start, stop, and control the position of actuators.

If additional actuator control is needed, for example, pressure control, flow control, sequence, pressure reducing, etc., it’s a simple case of inserting one, or more, of these valves in the form of “modules” between the sub-plate and directional control valve.

Due to the fact that the components are mounted on top of one another the assembly is typically referred to as a “stacked valve” assembly. Think of it as a hydraulic system without transmission lines.

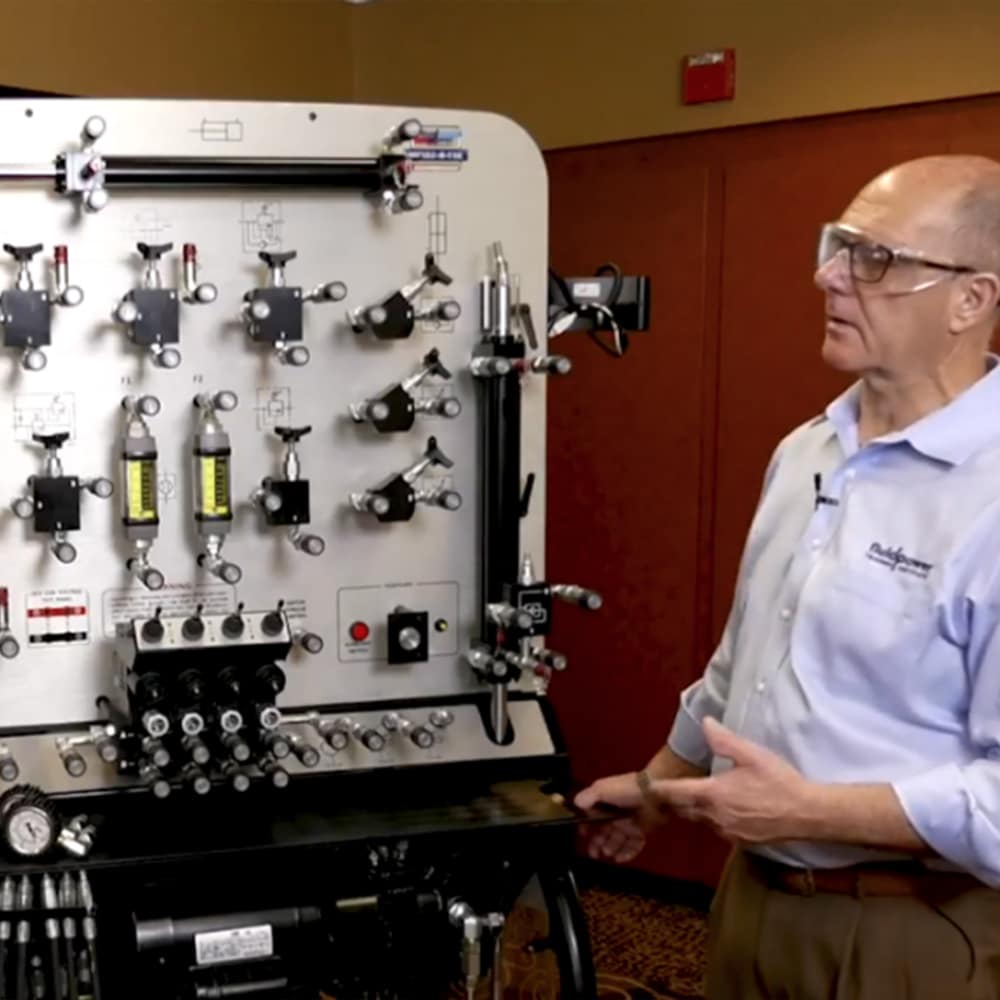

The MF100-SVM training module consists of the following components:

- 03 Sub-plate

- Pressure relief valve module

- Cross-port relief valve module

- Dual flow control valves module

- Dual pilot-operated check valves module

- Directional control valve

- Aluminum panel with integrated lined tray

- Steel back cover

Components that can be faulted:

- Pilot-operated check valve

- Cross-port relief valve

- Directional control valve

Learning outcomes

- Describe the advantages of “stacking” valves.

- Describe at least four practical applications for sub-plate mounted valves.

- Describe the international standards interface for sub-plate mounted valves

- Identify the sub-plates for 03, 05, 07, 08, and D10 valves.

- Identify the O-rings for 03, 05, 07, 08, and D10 valves.

- Identify at least four manufacturers of sub-plate mounted valves.

- Describe the difference between finite and infinite spool control.

- Describe the difference between a single-stage and two-stage valve.

- Describe the correct torque values for the retaining bolts for 03, 05, 07, 08, and D10 valves.

- Describe the correct bolt tightening sequence for the retaining bolts on stacked valve assemblies.

- Describe the correct assembly procedure for stacked valves