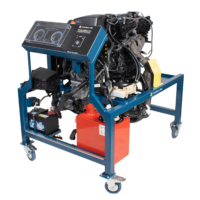

Description

Educational Advantages

- Saves significant instructor setup time for creating common engine mechanical faults and learning exercises

- Student assignments available

- Engine systems respond to inserted faults with real world symptoms, OEM DTC’s, scan tool data-stream of changes and Check Engine Light operation

- Repeatable faults allow multiple students to identify and demonstrate all required diagnostic tests required to identify cause (Prevents students from “memorizing” the faults. They would be required to perform the required testing)

- Installed mechanical faults cause compression, cylinder leak down, head gaskets and engine timing negative operational issues

Application

- 2013-2016 Toyota Corolla North American model 1.8L 2ZR-FE engine with automatic transmission.

Features

- Recycled engine, transmission and complete assembly of components

- A fully operational engine that starts/runs with OEM instrument panel

- Three “permanent” inserted industry common mechanical faults and one defective component fault that can be removed/replaced.

- Provides a “real world” running engine that will demonstrate all negative operational symptoms based on the faults.

- Functional Electronic Throttle Control, Catalytic Converter and Variable Valve Timing systems

- Emergency stop button

- Customized OEM exhaust system

- OEM Fuel Pump Module

- OEM power distribution center with circuit protection

- All electrical components match OEM wiring schematics and

service information - Automatic regulated 12V battery charger with master power

disconnect switch - Robust trainer frame and stand with special design features for:

– Easy removal and installation of radiator

– Front motor mount is removable providing access to front engine timing cover

– Defective control component that can be replaced with a non-defective unit correcting the fault

– Included tool storage tray

– Removable safety shields on all rotating components

– Additional instructor led engine component R&R (timing chain, etc)