Description

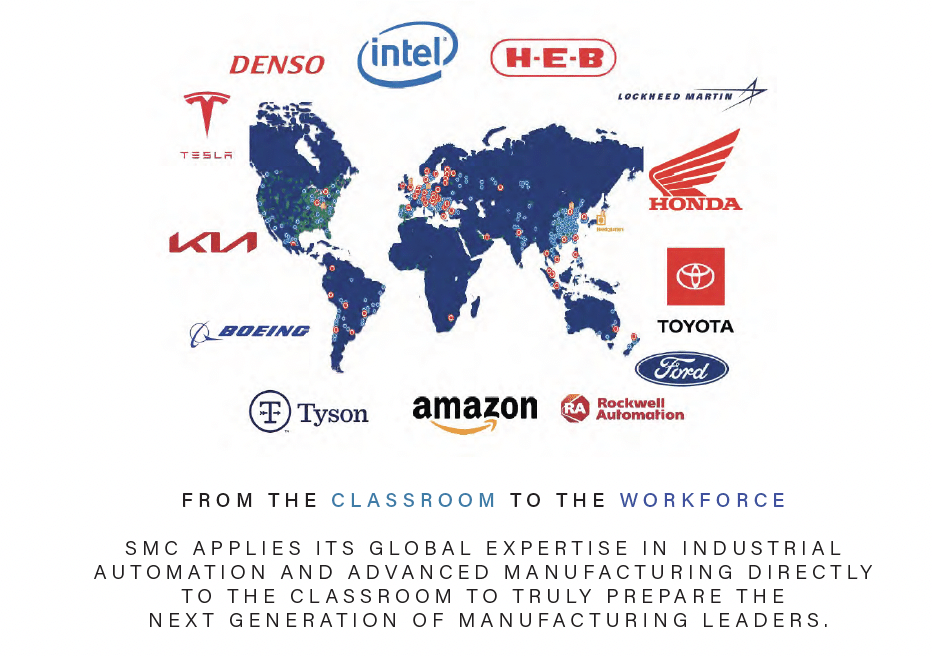

Compact and Powerful! Students develop skills in the most prevalent Industry 4.0 technologies, preparing them to thrive in a cyber physical world. The FAS-200 SE i4.0 system offers professional training within true industry context, simulating real assembly processes by leveraging core Industry 4.0 technologies.

Topics of Coverage

- – Industry 4.o Fundamentals and Processes

- – Industrial Communications and Protocols

- – Industry 4.o Design, Layouts, and Contextual Organization/Structure

- – Management Software and Tracking

- – PLC Programming and Structuring

- – Operating Modes

- – Material Flow

- – Distributed I/O

- – Identification Systems (RFID)

- – Smart Sensors and IO-Link

- – Integrated Systems Troubleshooting

FAS-209 – Cap Sorting Station

This station feeds and inspects the caps to be assembled on the product in process. There are 6 types of caps, depending on the material, color and height.

FAS-210 – Cap Rejection / Transfer Station

The central station rejects the caps or inserts them into the assembly depending on whether it is the desired type of cap for the current product. There are 2 versions: one where the transfer of caps is electro-pneumatic (pneumatic configuration) and another where the transfer is done by a collaborative robot (cobot configuration).

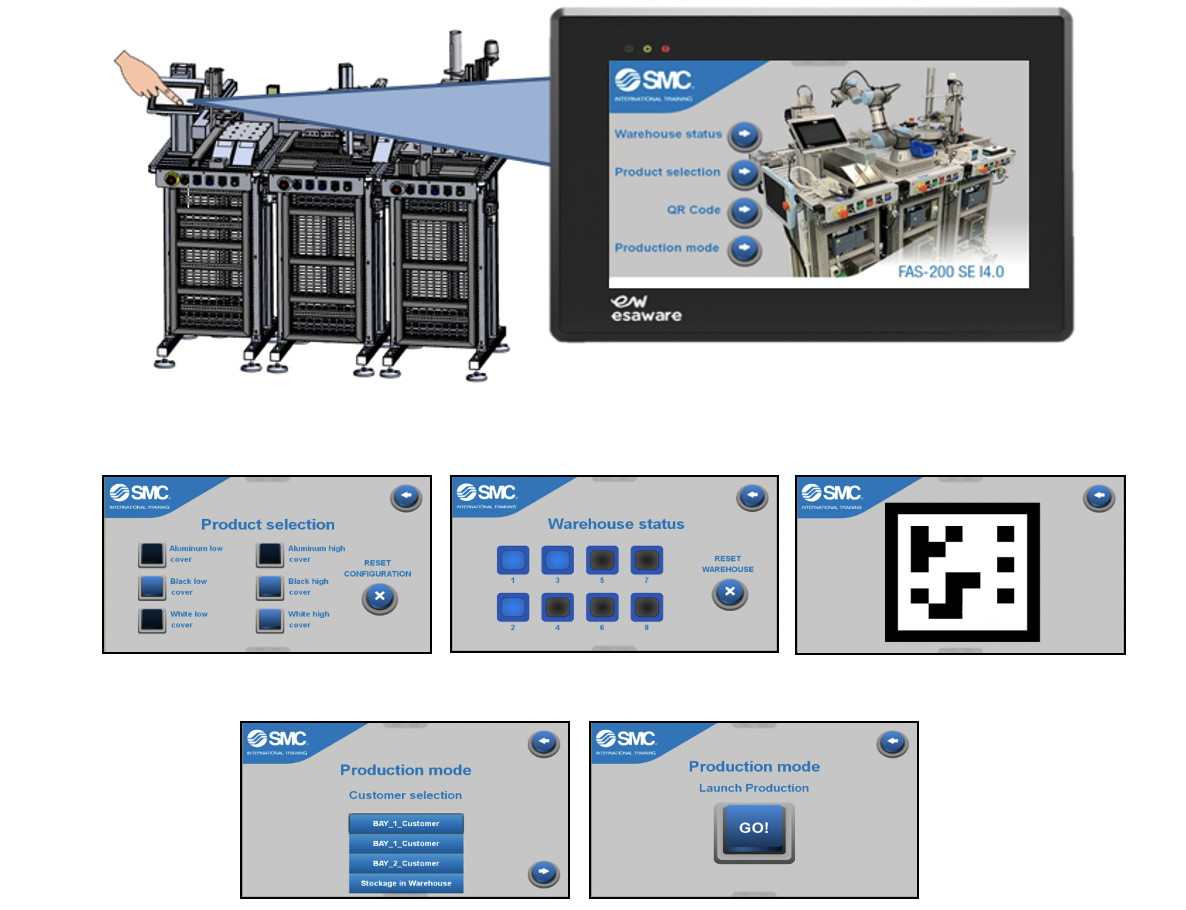

FAS-216 – Storage and Shipment Station

This station carries out the storage or shipment of the final product according to what has been previously set. It also includes the HMI screen that integrates the system management application.

Linear Transfer Station

A linear transfer system transports the pallet between the stations and connects them. It also integrates the RFID read/write systems for product traceability and the artificial vision system that allows verifying that the final product corresponds to the expected one.