Description

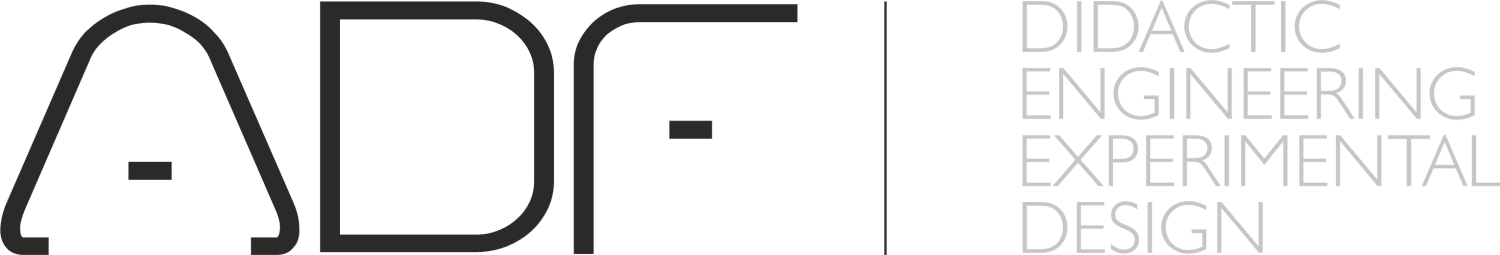

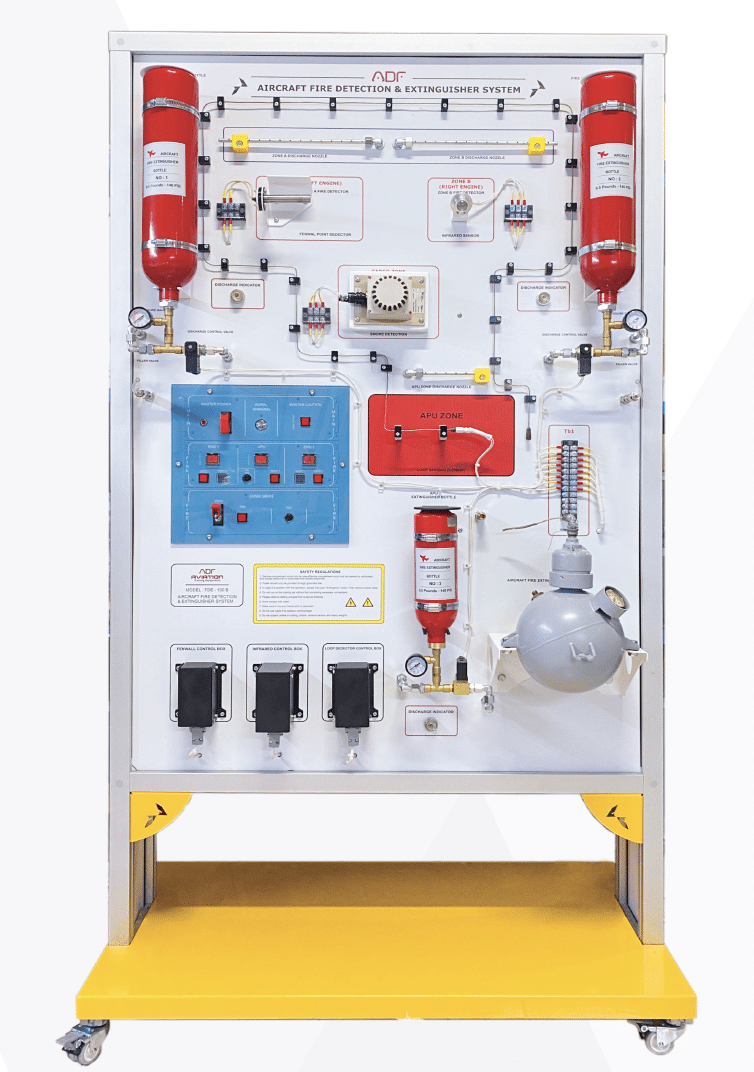

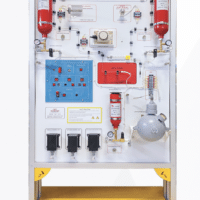

Understanding fundamentals of aircraft Fire Detection & Extinguishing system and its components. The Fire Detection and Extinguishing Training System has the following Features:

• Aircraft real fire & smoke scenarios are simulated.

• Fire is simulated on the training set with any sensor.

• The trainer is designed with three zones allowing Engine-1, Engine-2, APU fire and Cargo Smoke system simulation.

• Trainer includes separate extinguishers for each zone on the training set.

• The trainer include an original, emptied, secure aircraft extinguisher bottle for maintenance practices and using APU extinguisher bottle.

• Extinguishing system work crossfeed mode.

• Extinguishing bottle disassembly / assembly task

• Fire Extinguishing system test procedure task

• Sensor test procedure task

• Circuit breaker lockout application

Specifications

- Trainer set includes Engine1, Engine2, APU and forward cargo smoke system.

- Engine-1 fire warning is activated from fenwal detector.

- Engine-2 fire warning is activated from IR sensor.

- APU fire warning is activated from loop detector.

- Smoke warning is activated from smoke detector.

- Trainer set includes extinguisher bottle for all systems

- Extinguisher bottles have pressure gauge, pressure sensor and control valve.

Some of Trainer Functions

- Agent function

- FIRE push button function

- Discharge function

- Cross feed function

- Pumps fault function

- ECAM functions

- Single chime functions

- Master caution functions

- Master warning functions

The trainer has discharge nozzles for each zone (4 discharge nozzles).

Trainer includes three aluminum protection plates for heating sections on the loop sensor.

The complete loop sensor is mounted on the training set so that it could be clearly seen.

Trainer includes master warning, master caution and warning-horn system that could be reset.

Pressure sensors are for each bottle.

Wirings on the trainer are connected via terminals.

Wires should have clear identification labels for each wire.

All wires should be coded and labeled for troubleshooting.

Locked metal drawer for fault panel, document, heat gun and

Instructor’s panel for Fault Insertion

The system mounted on a metal/aluminum mobile stand.

Metal/aluminum frame with 4 wheels. 2 of 4 wheels are lockable.

Training video for teachers

Delivered fully assembled tested and ready to operate

Colored Ultraviolet printing method on aluminum composite panel

Documentation and Power Specs

- User’s Manual

- Study Guide

- Instructor’s Guide

- Components Diagrams

- Flow Diagrams

- Electrical box

- Residual current device

- Emergency Button

- Energy Signal Lamp

- 110 VAC 60 Hz or 220-240 VAC 50 Hz