Description

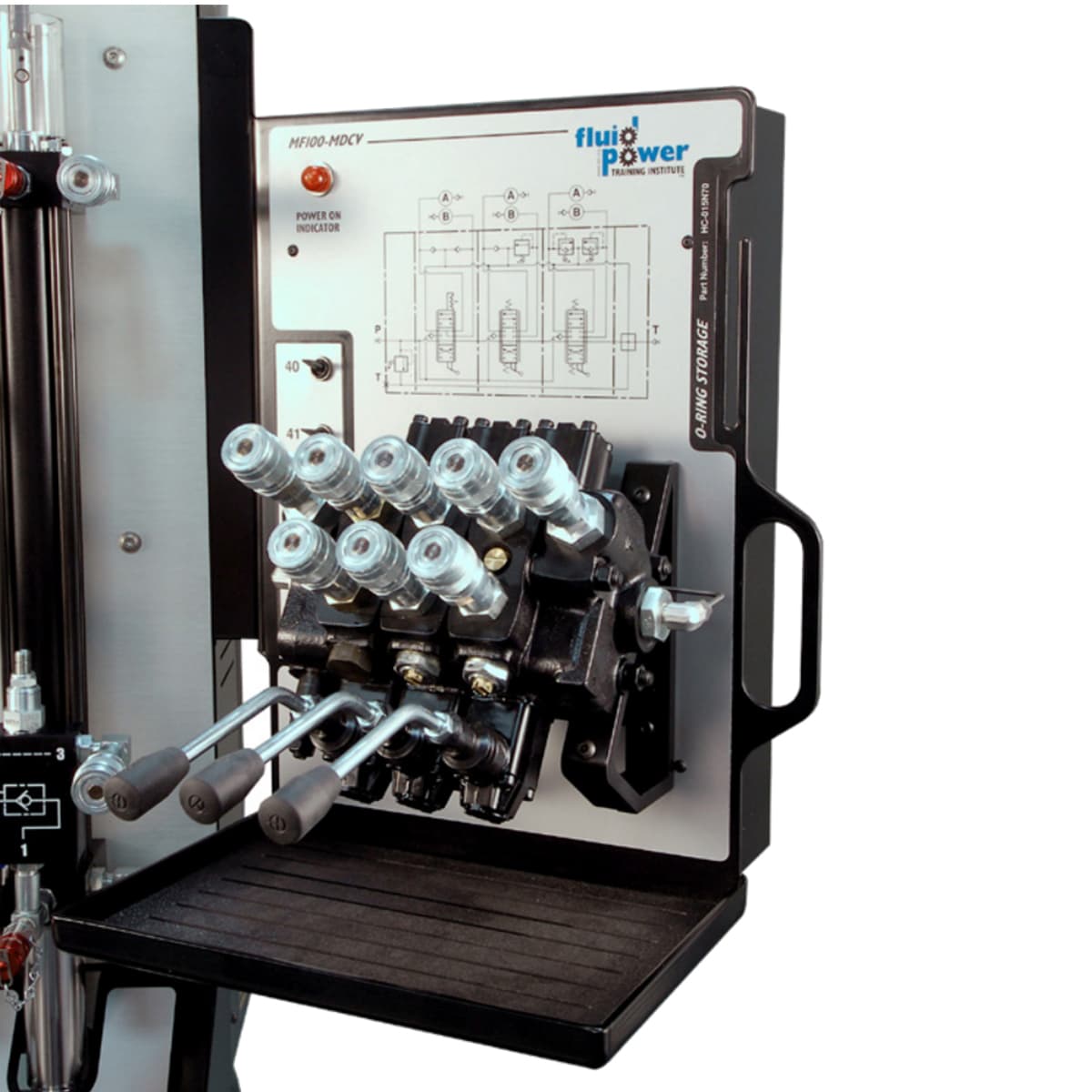

The MF100-MDCV is an actual directional valve assembly that is commonly used on machinery such as front-end loaders and forklifts. It is equipped with all the valves typically found in this type of mobile valve configuration which include: main pressure relief valve, load-check valves, cylinder port relief valves (line reliefs), and anti-cavitation valves. It also has two “cylinder” spools and a “motor” spool.

With the MF100-MDCV-TS students will learn to pressure/leak test individual sections with the objective of determining, with pinpoint precision, the condition of a given port. If there is unacceptable leakage in a given port the student will learn how to determine if the problem is related to spool/bore wear, cylinder port relief or anti-cavitation valve, or both.

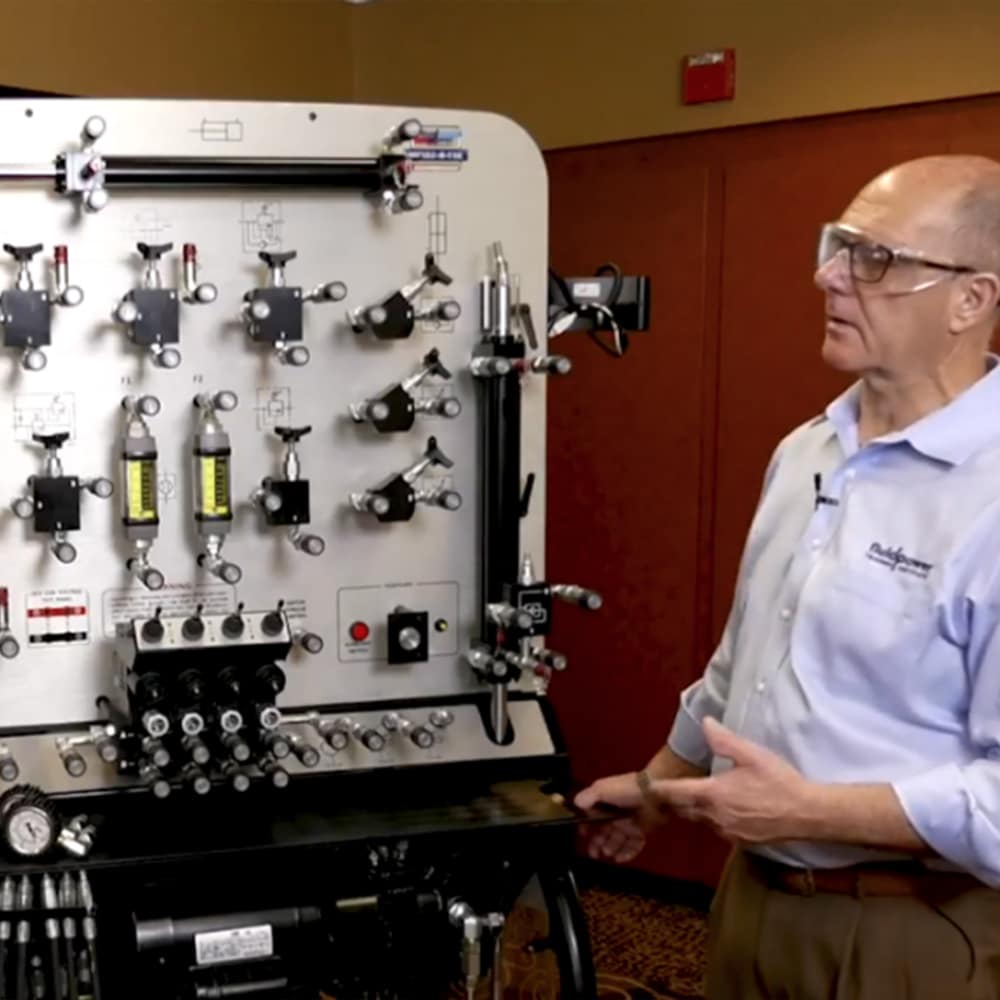

How the MF100-MDCV will benefit instructors and students

The MF100-MDCV three-section directional control valve is designed to operate in conjunction with the three (3) actuators on the MF102 series training simulators.

The “motoring spool” provides directional control functions for the hydraulic motor, and the two “cylinder spools” provide directional control functions for the two cylinders.

The lesson (included with simulator) allows instructors to demonstrate the following procedures:

- The purpose of the main pressure relief valve

- How the main pressure relief valve functions

- How to safely and properly set a main pressure relief valve

- The purpose of a cylinder port relief valve

- How a cylinder port relief valve functions

- How to safely and properly set cylinder port relief valves

- The purpose of a load check valve

- How a load-check valve functions

- The purpose of an anti-cavitation valve

- How an anti-cavitation valve functions

- The purpose of power-beyond

- How a power-beyond circuit functions

- How to read a hydraulic schematic for a typical mobile directional control valve