Electrical

Toolkit is proud to offer schools the very best Electrical Training Systems available for students to build their understanding and mastery of electrical technologies. The building blocks for careers in multiple pathways, electrical technologies are the important foundational learning blocks for students as they begin their studies.

Mastering electrical skills will lead to successful careers in fields such as Advanced Manufacturing, Skilled Trades, Mechatronics, HVAC, Alternative Energy, and Automotive Technologies, and more.

Electrical Skills

Students must learn basic concepts of electricity and electrical measurements. They must be able to analyze circuits, troubleshoot circuits, and understand differences between Alternating Currents (AC) and Direct Currents (DC). Learners will be expected to understand basic topics including inductance, capacitance, combination circuits, and transformers, along with series and parallel circuits.

Learners will be expected to wire industrial devices while also understanding electrical safety.

Job Outlook

Most jobs in CTE require a strong foundation in electrical technologies and concepts. From electricians to technicians, jobs in the electrical field are growing in need and pay. As technologies and systems grow more complex and advanced, the demand for increased training in electrical technologies is also growing.

Toolkit’s hands-on training systems combined with digital simulation solutions and eLearning provides students with needed industry-validated skills and certifications.

Showing all 2 results

-

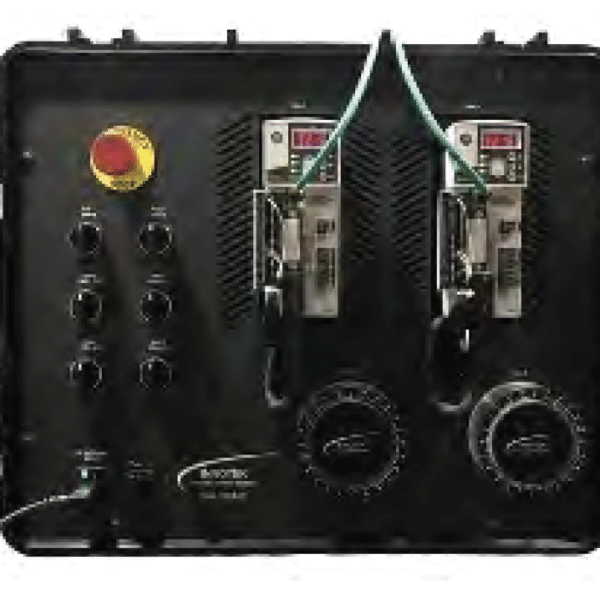

Servo (Drives) Motion Training System

The Servo Motion Training System provides participants with hardware allowing for hands-on experiments in setup,

configuration and programming and servo drives for rotary or linear motion. The system gives access to onboard input and

output devices in addition to providing connectivity for external devices.

The system can be purchased with a Motion-Capable PLC or utilized in combination with an existing motion-capable PLC.

Tabletop or Suitcase Form Factor

- 120Vac Power Entry

- Emergency Stop

- (3) Selector Switches (Enable, + Over-Travel, – Over-Travel)

- (2) Homing Sensors

- (2) Servo Rotary Axis

- (2) Servo Drives

-

Conveyor and Logistics Automation Training System

The Conveyor and Logistics Automation Training System with Troubleshooting is our industrial training solution for school and companies looking for practical and realistic hands-on training activities in areas such as Maintenance, Troubleshooting, and Programming of industrial automation technologies commonly seen in warehouses, logistics settings, and industrial automation factories.

The mobile and modular system includes choices of PLC controller, Variable Frequency Drive, HMI’s, and conveyors. Conveyors stations can include: flatbed slider belt conveyors, roller bed belt conveyors, powered roller conveyor, plastic mesh conveyor, and more.

Up to 32 Troubleshooting Faults can be incorporated so students can troubleshoot and repair faulted components.