Mechatronics

Mechatronics is the big-strange word that covers so much. The marriage of mechanical, electrical, computer and software skills in order to work with smart technologies, TOOLKIT prepares students for various career pathways within the ever-changing landscape of Mechatronics.

Students learn integrated systems that combine electrical technologies with mechanical technologies and computer programming for real-world skills that directly relate to modern jobs in manufacturing and automation.

Mechatronics sits at the intersection of mechanics, electronics, and computing, and is built on the idea of creating simpler and smarter systems. Toolkit provides the training systems that empower mechatronics technicians and specialists with the skill sets to thrive in contemporary, advanced automated manufacturing industries.

Electro-mechanical technologists and technicians combine knowledge of mechanical technology with knowledge of electrical and electronic circuitry. They operate, test, and maintain unmanned, automated, robotic, and/or electromechanical equipment.

Electro-mechanical and mechatronics technologists and technicians typically do the following:

- Read blueprints, schematics, and diagrams to determine the method and sequence of assembly of a machine or a piece of equipment

- Verify dimensions of parts, using precision measuring instruments

- Operate metalworking machines to make housings, fittings, and fixtures

- Inspect parts for surface defects

- Repair and calibrate hydraulic and pneumatic assemblies

- Use instruments to test the performance of electromechanical assemblies

- Use soldering equipment and hand tools to install electronic parts and hardware

- Operate, test, or maintain robotic equipment

- Analyze and record test results

They install, maintain, and repair automated machinery and computer-controlled mechanical systems in industrial settings, and also test, operate, and/or maintain robotic equipment at worksites. This equipment may include unmanned submarines, aircraft, or similar types of equipment for uses that include oil drilling, deep-ocean exploration, or hazardous-waste removal.

They average pay for someone with these skills is over $61,040.00.

Showing all 3 results

-

Conveyor and Logistics Automation Training System

The Conveyor and Logistics Automation Training System with Troubleshooting is our industrial training solution for school and companies looking for practical and realistic hands-on training activities in areas such as Maintenance, Troubleshooting, and Programming of industrial automation technologies commonly seen in warehouses, logistics settings, and industrial automation factories.

The mobile and modular system includes choices of PLC controller, Variable Frequency Drive, HMI’s, and conveyors. Conveyors stations can include: flatbed slider belt conveyors, roller bed belt conveyors, powered roller conveyor, plastic mesh conveyor, and more.

Up to 32 Troubleshooting Faults can be incorporated so students can troubleshoot and repair faulted components.

-

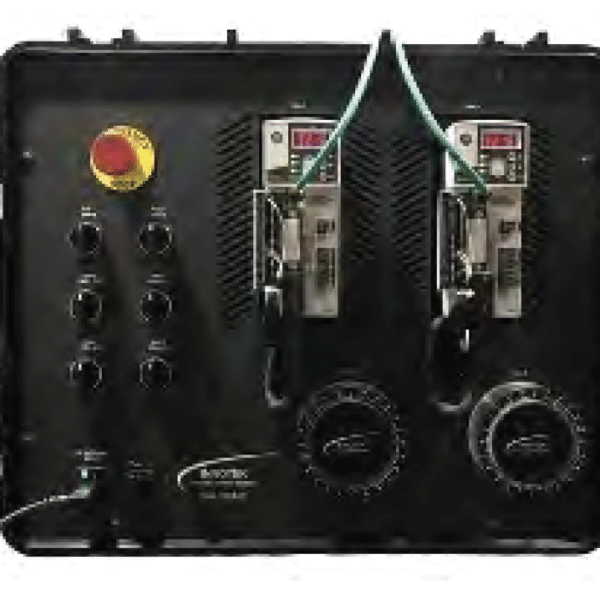

Servo (Drives) Motion Training System

The Servo Motion Training System provides participants with hardware allowing for hands-on experiments in setup,

configuration and programming and servo drives for rotary or linear motion. The system gives access to onboard input and

output devices in addition to providing connectivity for external devices.

The system can be purchased with a Motion-Capable PLC or utilized in combination with an existing motion-capable PLC.

Tabletop or Suitcase Form Factor

- 120Vac Power Entry

- Emergency Stop

- (3) Selector Switches (Enable, + Over-Travel, – Over-Travel)

- (2) Homing Sensors

- (2) Servo Rotary Axis

- (2) Servo Drives

-

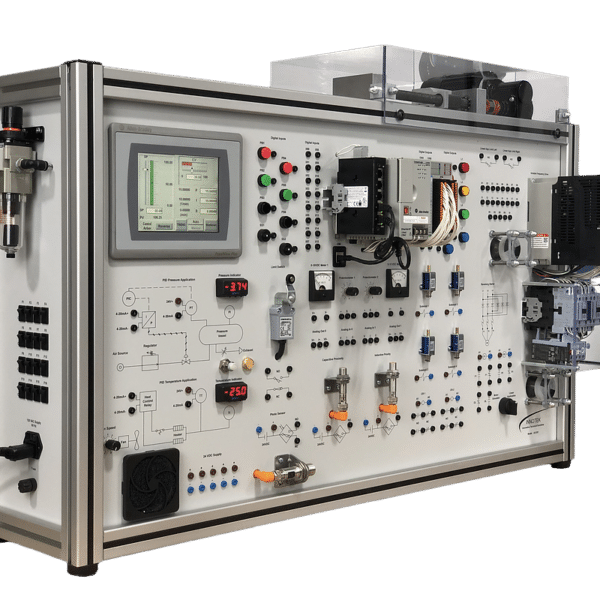

PLC Automation Training System | all-in-one

The ATS-200 Automation Training System provides students with a hardware platform for performing hands-on skills development activities for automation technologies operations. The tabletop or mobile platform includes various applications which can be quickly connected to provide advanced activities, expanding the learning objectives beyond simple on/off functionality.

The all-in-one PLC Training System includes:

◉ Operator Control Application

◉ Sensors and Switches Application

◉ Pneumatic Actuator/Valve Application

◉ Linear Ball Screw Application

◉ BCD Thumbwheel and 7 Segment Display

◉ Dual Analog Potentiometer and Meters

◉ Motor Control Application

◉ Variable Speed Drive (Any Brand)

◉ PLC (Any Brand)

◉ HMI (Any Brand)

◉ PID Pressure Application

◉ PID Temperature Application

The system shown as tabletop trainer with banana jack connections. The unit can be purchased with a mobile frame with all components pre-wired to the PLC requiring no additional connections.