Fluid Power

Fluid Power technology is the often-overlooked workhorse behind modern manufacturing and automation of all kinds. Toolkit is proud to bring industry-standard technologies from global leading manufacturers into students’ hands with our remarkable Fluid Power Training Systems.

What is Fluid Power?

Encapsulating both hydraulics and pneumatics, fluid power leverages fluids (or air) under pressure to generate, control, and transmit power from one location to another.

Fluid power systems easily produce linear motion using hydraulic or pneumatic cylinders, whereas electrical and mechanical methods usually must use a mechanical device to convert rotational motion to linear.

Why Fluid Power Training?

Understand fluid power, controlling it, and troubleshooting fluid power circuits is vital to careers in many industrial segments – Manufacturing and Advanced Manufacturing, Heavy Truck and Agriculture Mechanics, Alternative Energy and More.

Did you know that fluid power technologies surround us everyday? Some example of this include: gas pumps; car brakes, dishwashers, airplanes, elevators, amusement park rides, office chairs, and more!

Fluid Power Training Outcomes

With Toolkit, we bring countless years experience as industry leaders into the classroom, with best-in-class fluid power training systems, curriculum, and digital simulation solutions to provide your students with the best hands-on skills training available. Validating student competencies, providing lifelong skills, and empowering students through industry certification.

Industry Skills

Our goal is to empower student success in the workforce through hands-on skills development in topics such as:

– Pneumatics and Electropneumatics

– Pneumatic Directional Control Valve Applications

– Maintenance and Servicing Pneumatic Components

– Air Logic

– Cylinder Loads and Pneumatic Motor Loads

– Component Sizing

Showing the single result

-

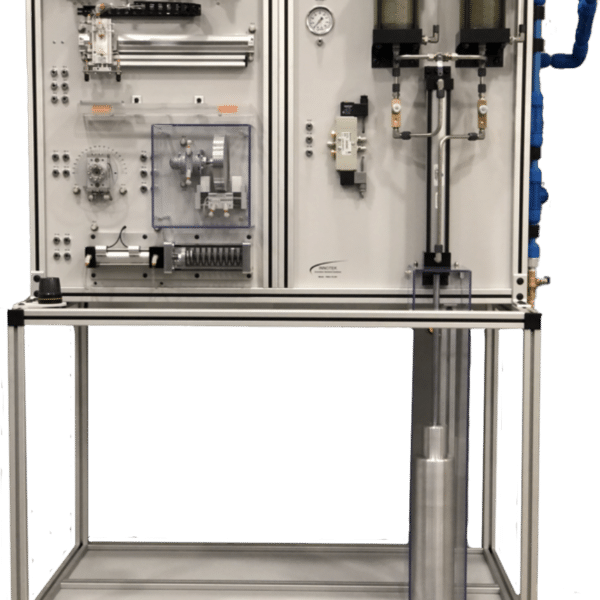

Pneumatic Troubleshooting Training System

Take your Pneumatics training to the next level with our new, hands-on Pneumatic Troubleshooting Training System.

The PNEU-TS-201 Training system provides participants with hardware allowing for hands-on activities in troubleshooting of industrial pneumatic applications. This system gives access to various electrical and pneumatic components which are connected to create six unique applications. The operator control section allows for direct manual and automatic control of each application. Lastly the system includes fault insertion capability to assist in development of a systematic approach to troubleshooting.

The Pneumatic Troubleshooting Training System is the most capable and comprehensive pneumatics training aid of its kind. Complete with Pick & Place, Loading Actuator, Rotary Manipulator, Free Wheeling Motor/Brake, Air Over Oil, and Operator Control Station.