Mechatronics

Mechatronics is the big-strange word that covers so much. The marriage of mechanical, electrical, computer and software skills in order to work with smart technologies, TOOLKIT prepares students for various career pathways within the ever-changing landscape of Mechatronics.

Students learn integrated systems that combine electrical technologies with mechanical technologies and computer programming for real-world skills that directly relate to modern jobs in manufacturing and automation.

Mechatronics sits at the intersection of mechanics, electronics, and computing, and is built on the idea of creating simpler and smarter systems. Toolkit provides the training systems that empower mechatronics technicians and specialists with the skill sets to thrive in contemporary, advanced automated manufacturing industries.

Electro-mechanical technologists and technicians combine knowledge of mechanical technology with knowledge of electrical and electronic circuitry. They operate, test, and maintain unmanned, automated, robotic, and/or electromechanical equipment.

Electro-mechanical and mechatronics technologists and technicians typically do the following:

- Read blueprints, schematics, and diagrams to determine the method and sequence of assembly of a machine or a piece of equipment

- Verify dimensions of parts, using precision measuring instruments

- Operate metalworking machines to make housings, fittings, and fixtures

- Inspect parts for surface defects

- Repair and calibrate hydraulic and pneumatic assemblies

- Use instruments to test the performance of electromechanical assemblies

- Use soldering equipment and hand tools to install electronic parts and hardware

- Operate, test, or maintain robotic equipment

- Analyze and record test results

They install, maintain, and repair automated machinery and computer-controlled mechanical systems in industrial settings, and also test, operate, and/or maintain robotic equipment at worksites. This equipment may include unmanned submarines, aircraft, or similar types of equipment for uses that include oil drilling, deep-ocean exploration, or hazardous-waste removal.

They average pay for someone with these skills is over $61,040.00.

Showing the single result

-

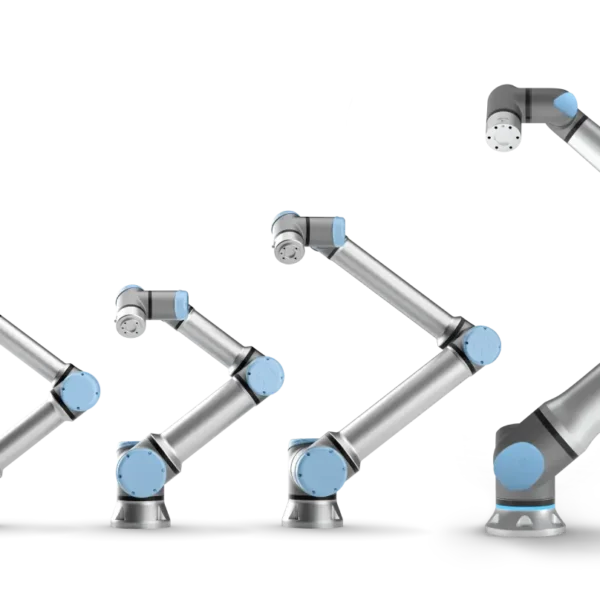

Universal Robots Collaborative Robots

Toolkit Technologies is proud to offer Universal Robots’ industry-leading collaborative robots to education and training institutions around the country.

Empower your students with cutting-edge industrial skills training solutions using Universal Robots’ collaborative robots. Our hands-on training systems, featuring all-industrial technologies sourced from industry leaders like SMC, UR, Miller Electric, and others, immerse learners in real-world applications that prepare them for dynamic careers in today’s tech-driven workforce.

Elevate your educational programs with our state-of-the-art robotics technology, fostering innovation and expertise in your students. Explore our range of training solutions now for comprehensive technical education solutions that drive future success.

We are proud to offer robust curriculum, eLearning, on-site training, and custom training applications with every UR Robot.

Let us know what robotics application you want to teach, and we’ll build it!