Mechatronics

Mechatronics is the big-strange word that covers so much. The marriage of mechanical, electrical, computer and software skills in order to work with smart technologies, TOOLKIT prepares students for various career pathways within the ever-changing landscape of Mechatronics.

Students learn integrated systems that combine electrical technologies with mechanical technologies and computer programming for real-world skills that directly relate to modern jobs in manufacturing and automation.

Mechatronics sits at the intersection of mechanics, electronics, and computing, and is built on the idea of creating simpler and smarter systems. Toolkit provides the training systems that empower mechatronics technicians and specialists with the skill sets to thrive in contemporary, advanced automated manufacturing industries.

Electro-mechanical technologists and technicians combine knowledge of mechanical technology with knowledge of electrical and electronic circuitry. They operate, test, and maintain unmanned, automated, robotic, and/or electromechanical equipment.

Electro-mechanical and mechatronics technologists and technicians typically do the following:

- Read blueprints, schematics, and diagrams to determine the method and sequence of assembly of a machine or a piece of equipment

- Verify dimensions of parts, using precision measuring instruments

- Operate metalworking machines to make housings, fittings, and fixtures

- Inspect parts for surface defects

- Repair and calibrate hydraulic and pneumatic assemblies

- Use instruments to test the performance of electromechanical assemblies

- Use soldering equipment and hand tools to install electronic parts and hardware

- Operate, test, or maintain robotic equipment

- Analyze and record test results

They install, maintain, and repair automated machinery and computer-controlled mechanical systems in industrial settings, and also test, operate, and/or maintain robotic equipment at worksites. This equipment may include unmanned submarines, aircraft, or similar types of equipment for uses that include oil drilling, deep-ocean exploration, or hazardous-waste removal.

They average pay for someone with these skills is over $61,040.00.

Showing all 7 results

-

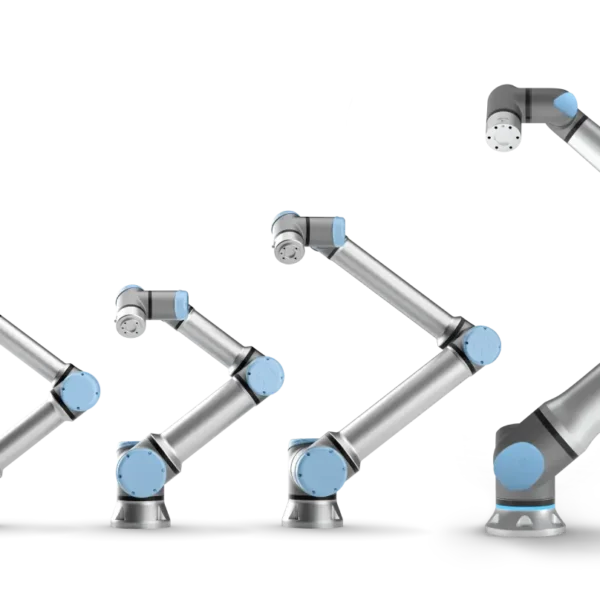

Universal Robots Collaborative Robots

Toolkit Technologies is proud to offer Universal Robots’ industry-leading collaborative robots to education and training institutions around the country.

Empower your students with cutting-edge industrial skills training solutions using Universal Robots’ collaborative robots. Our hands-on training systems, featuring all-industrial technologies sourced from industry leaders like SMC, UR, Miller Electric, and others, immerse learners in real-world applications that prepare them for dynamic careers in today’s tech-driven workforce.

Elevate your educational programs with our state-of-the-art robotics technology, fostering innovation and expertise in your students. Explore our range of training solutions now for comprehensive technical education solutions that drive future success.

We are proud to offer robust curriculum, eLearning, on-site training, and custom training applications with every UR Robot.

Let us know what robotics application you want to teach, and we’ll build it!

-

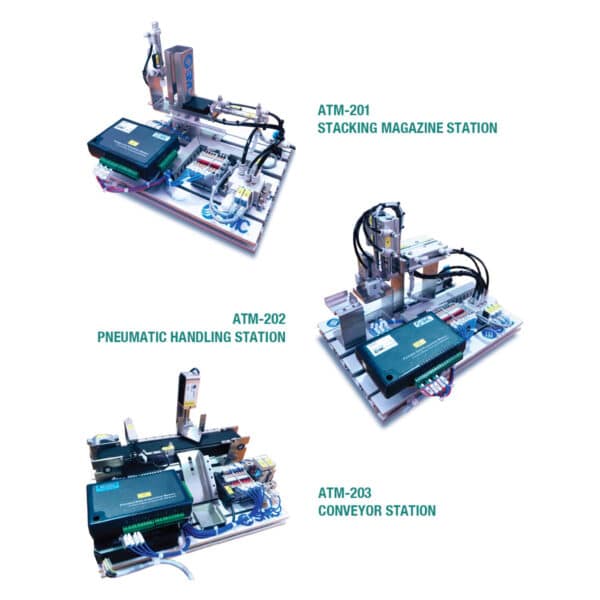

SMC Tabletop Intro to Automation Training Modules (ATM-200)

SMC’s tabletop intro to Automation Training Module, ATM-200, is the perfect training system for high school automation, mechatronics, and exploratory career pathways. Learn and acquire hands-on skills in electricity, pneumatics, programming, sensors, and more!

Each training module consists of (3) tabletop training stations and site license to autoSIM simulation software for virtual training in pneumatics, electrical, hydraulics, and control circuits.

-

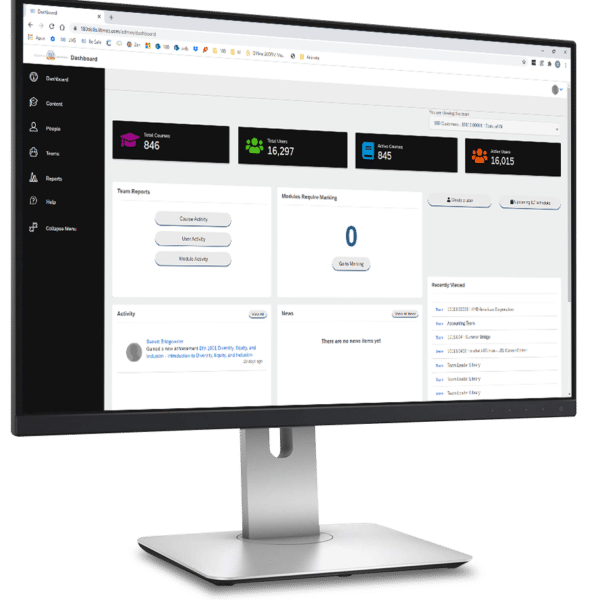

CTE + Workforce eLearning

Toolkit is proud to partner with Valor, 180 Skills, and SMC to bring you the most complete, thorough, and comprehensive eLearning solution for Career and Technical Education. An AWARD-WINNING Learning System for CTE, Workforce Development, and Industry Training.

Web-based eLearning content in over 900 courses – ranging from Career and Technical Education skills, Workforce Development training, Soft Skills development, and more!

Our new eLearning is the most comprehensive skills-based training program out there for real-world skills, certifications, and job-ready outcomes.

Over 600 Technical Skills Courses!

Over 200 Employability and Soft Skills Courses!

Over 80 Quality + Compliance Skills Courses!

-

SMC eLearning

SMC eLEARNING-200 is a flexible, web-based learning platform for skills-based, industry-driven learning to take place anywhere, anytime there is the motivation to learn!

Users can develop skills and theoretical knowledge around Automation and Technical topics such as Robotics, PLCs, Electrical, Pneumatics, Hydraulics, Motors, Sensors and More.

-

Werk Wagon Portable Training Center

Toolkit is proud to offer schools and training facilities a completely customizable and mobile solution for workforce training, STEM education, CTE skills development with our new WERK WAGON portable training centers!

Completely customizable, modular and portable training in a whole new way. Our Werk Wagon is perfect for schools looking to bring their training and expertise into the community, or share resources between schools, or with physical space limitations that require larger bond and/or construction money. Toolkit’s Werk Wagons are mobile, portable Workforce Training Centers and simply amazing!

Customizable sizes, dimensions, and physical features allow these mobile training centers to fit perfectly to your needs and to focus on your needed training areas.

-

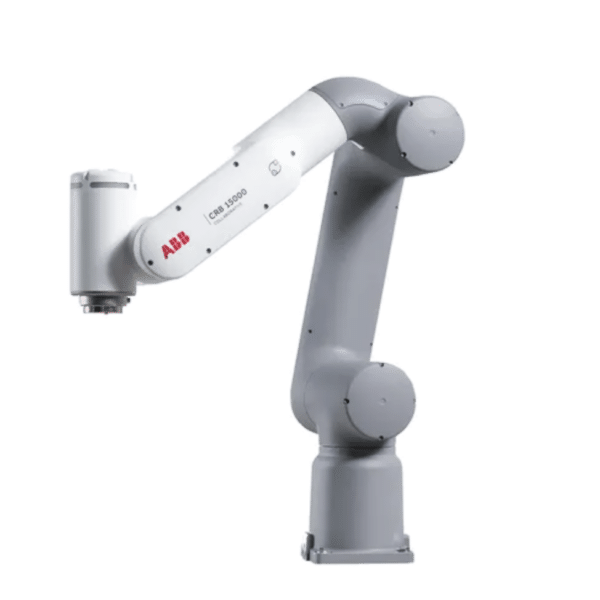

ABB GoFa CRB 15000 Collaborative Robot

Go Faster! Go Farther! Go Further! Go Train!

We are thrilled to bring ABB’s newest collaborative robot, the GoFa, with industry leading speed, precision, reach and more!

Ease-of-use is in focus here – with enhanced user-interaction capabilities, superior lead through, and ABB Wizard easy programming, training robotics and automation has never been more accessible.

Students can get hands-on industry-driven robotics experience from day 1 with unlimited training potential! Understanding the advantages of collaborative robotics and automation, machine tending, welding, pick & place, etc. has never been easier!

-

ABB IRB 14000 YuMi Collaborative Robot

The first robot to do it. Collaboratively. Uniquely and Effectively. She grabs attention and keeps it.

Best-in-class safety. Ultimate flexibility. Approachable design. ABB’s YuMi robot was engineered to work directly alongside your people and students, and boost productivity and training.

YuMi is the first truly collaborative dual-armed robot, designed for a world in which humans and robots work together. It heralds a new era of robotic coworkers which are able to work side-by-side on the same tasks as humans with extreme accuracy while ensuring the safety of those around it.

Available in single or double-arm configurations.