How Concrete 3D Printing Is Revolutionizing the Construction Industry

An Industry Prime for Automation

The construction industry is an ever-evolving industry, with new technologies being adopted every few years that promise to revolutionize the way we build. The latest technology to enter the building scene is concrete 3D printing (C3DP). This new technology is transforming the construction industry by allowing for faster and more efficient construction projects. In this blog post, we will discuss how concrete 3D printing is revolutionizing the construction industry and why it is becoming the go-to technology for many construction projects.

What is Concrete 3D printing?

Concrete 3D Printing is the perfect solution for complex structures and building projects that require precision and intricate detail. This technology allows for the rapid fabrication of complex structures that would otherwise take a long time to create using traditional construction methods.

The 3D printer is operated by complex computations the printer to place the proper amount of concrete in the exact desired location, at the proper rate, flow, and width. The concrete is then cured, or hardened, and forms the final product.

With concrete 3D printing, architects and engineers have the ability to create custom structures that conform to the exact specifications of their clients, but also have the ability to completely reimagine the way structures are built in comparison with traditional building methods. This technology also allows for structures to be built quickly and efficiently, making it an ideal solution for large-scale construction projects. This is increasingly interesting as the global labor shortage continues to grow.

Concrete 3D Printing is revolutionizing the construction industry by making it faster, more efficient, and more cost-effective. The technology is expected to become even more popular in the coming years, making it an important part of the future of construction.

How is Concrete 3D Printing Transforming the Construction Industry?

Increased focuses on sustainable building methods, labor, lowering construction costs and increasing housing accessibility and availability has created an environment apt for automation and disruption. Concrete 3D printing is poised to address these factors, and promises to re-shape the way homes, buildings, and infrastructure is built in the near future.

The Advantages of Concrete 3D Printing

Concrete 3D printing is revolutionizing the construction industry, offering a range of advantages that are making it the go-to option for many projects. By using 3D printing technology, construction projects are becoming faster and more efficient. With fewer labor costs associated with traditional construction methods, projects can be completed in a fraction of the time.

New Design and Construction Possibilities

In addition, 3D printing allows for more intricate and complex designs to be created with ease. With 3D printing, construction teams can create unique buildings with unique designs that can be customized to meet the needs of any project. This allows for more flexibility in design and fewer limitations that may have been present with traditional construction methods.

Reduced Carbon Emissions

3D printing is an environmentally friendly solution for constructing buildings. It is a much more efficient process that requires fewer resources than traditional construction methods, resulting in fewer emissions and waste. This makes it a great option for those looking to reduce their environmental impact while still creating beautiful structures.

New Construction Materials

Furthermore, there is a large focus on materials research and allows printers to build with more than solely traditional concrete. Many companies are exploring the ability to print with materials composed of Hemp, Paper, Clay, and more.

Overall, concrete 3D printing is revolutionizing the construction industry and offering a range of advantages that make it the go-to option for many projects. With faster construction times, reduced labor costs, more intricate designs, and an environmentally friendly solution, it is becoming the preferred method for many construction projects.

The Challenges of Concrete 3D Printing

The construction industry is quickly discovering that concrete 3D printing has the potential to revolutionize the way we build homes and other structures. This groundbreaking technology is cost-effective, efficient, and environmentally friendly, making it an attractive option for builders and architects. However, despite its potential, there are still a few challenges that need to be addressed before 3D printing can become a mainstream construction method.

Cost-Effectiveness

One of the biggest challenges of 3D printing concrete is its cost-effectiveness compared to traditional construction methods. Although 3D printing is faster and more efficient, it still requires a significant initial investment in equipment, training, and materials. It also requires specialized expertise in order to operate the machinery, which can be costly. However, as 3D printing technology continues to advance, the cost of 3D printing is becoming more affordable and accessible.

Changing Mindsets

Another challenge is the potential of 3D printing to revolutionize the construction industry. Although 3D printing can drastically reduce the amount of time and resources needed to build a structure, it is still a relatively new technology that requires specialized expertise and training to use. As such, it can be difficult to find experienced 3D printing professionals and to train existing personnel in the necessary skills.

Waste

Finally, there is the challenge of environmental benefits. While 3D printing concrete eliminates the need for many materials associated with traditional construction methods, it can still produce a lot of waste. In addition, the energy required to power 3D printers is often higher than traditional construction methods.

Permitting + Certification

Concrete 3D Printing is at its infancy, and as such challenges around certifying new-build construction is a major challenge. Currently, there is research being done across the world to see how dwellings and building constructed with this technology withstand to environmental factors such as flooding, earthquakes, shifting, etc.

Despite these challenges, 3D printing concrete is becoming more accessible and efficient. As technological advances continue to be made, 3D printing is becoming a viable and cost-effective option for construction projects. With the right tools and training, 3D printing can truly revolutionize the way we build homes and other structures.

Leaders in Concrete 3D Printing

The construction industry is on the cusp of a revolution. Concrete 3D Printing is providing a new way to construct buildings, bridges, and other structures in a fraction of the time and cost of traditional methods. Pioneering companies such as ICON and XtreeE are leading the way in this new technology, making it possible for projects to be completed faster and with greater precision than ever before.

ICON

ICON, based in Austin, Texas, has been at the forefront of Concrete 3D Printing since they first introduced their Vulcan 3D Printer in 2018. The Vulcan has already been used to construct dozens of homes around the world, including the first permitted 3D-printed home in the United States. ICON’s technology has been used to construct homes, schools, and other structures, promising a much-needed solution to the global housing crisis.

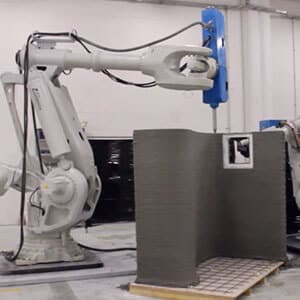

XtreeE Large-Scale 3D Printing

XtreeE is another pioneering company that has taken Concrete 3D Printing to a whole new level with their XtreeE Robotic 3D Printing System. XtreeE uses ABB Robot Arms to construct large-scale structures with unprecedented speed and accuracy. Together with the xHead, xFeed, and mixer and pump, XtreeE offers a complete solution with full transparency of furthering the mission of the concrete 3D printing industry as a whole. Their system has been used to construct a bridge across a river in France, a public plaza in Australia, furniture, housing, telecommunication towers, a multi-story building in Dubai, and more.

XtreeE Advantages

The XtreeE Robotic 3D Printing System has several advantages over traditional methods of construction. It can print structures in any size or shape, and can be used to construct complex structures in a fraction of the time and cost of traditional methods. Furthermore, the system is highly automated and requires minimal human intervention, which drastically reduces labor costs and makes it possible for projects to be completed faster.

A key advantage of the XtreeE system as opposed to the gantry-based approaches seen by companies like ICON is the methodology by which XtreeE believes Concrete 3D Printing structures can be accessible to the masses and cost effective: rather than setting up a large printing system on-site at every construction site which can be prohibitive and costly, XtreeE “prints” can be manufactured and shipped directly to construction sites for assembly. Not only can this be seen as more practical, cost-effective and sustainable, but allows for wider implementation.

Concrete 3D Printing is revolutionizing the construction industry, and companies like ICON and XtreeE are leading the way. With their pioneering technology, they are making it possible for projects to be completed faster and with greater precision than ever before.

The Future of Concrete 3D Printing in the Construction Industry

The future of concrete 3D printing in the construction industry is incredibly exciting. With the emergence of this new technology, the potential for construction projects to be completed quickly and cost-effectively is now a reality. Concrete 3D printing is a game-changing technology that has the potential to revolutionize the construction industry.

Concrete 3D printing involves using an automated printer to quickly and precisely build structures out of concrete. This technology can be used to create everything from small scale decorative pieces to large scale buildings. The advantages of this technology are numerous, including improved accuracy, reduced labor costs and faster construction times.

Not only is 3D printing cheaper and faster than traditional building methods, it is also much more environmentally friendly. This technology uses less material, resulting in reduced waste and fewer emissions. Additionally, 3D printing can be done with recycled materials, making it a sustainable building option.

The potential of concrete 3D printing to revolutionize the construction industry is immense. The technology can be used to build customized, complex structures that would be impossible to build with traditional methods. Additionally, 3D printing can be used to build structures with features and functions that would not be possible with other building methods.

Ultimately, concrete 3D printing is revolutionizing the construction industry and has the potential to completely transform the way we build. By providing an efficient, cost-effective and environmentally friendly alternative to traditional building methods, 3D printing is revolutionizing the construction industry, making it easier and faster than ever to build complex structures.

How Should We Prepare Students for this New Reality?

The construction industry is currently undergoing a revolution, thanks to the introduction of concrete 3D printing. This technology is allowing architects and builders to create structures that would have been impossible just a few years ago. As this technology develops and becomes more widely accepted, students will need to be prepared to navigate this new reality.

Materials

The first step in preparing students for a future in which 3D printing is widely used in the construction industry is to ensure they are familiar with the materials and sustainable construction technologies that are being used. This includes introducing students to materials such as recycled plastics, concrete and glass, as well as new techniques for manufacturing and assembling them. Students should also be educated on the basics of 3D printing, as well as its advantages and limitations.

Robotics + Computational Design

In addition to knowledge of the materials and technologies being used in the construction industry, students should also receive cross-disciplinary training in areas such as robotics, computational design and digital fabrication. This will allow them to explore entirely new ways of building and constructing, and will give them the skills they need to work with 3D printing technology.

Critical Thinking

Finally, students should be encouraged to think critically and creatively about the potential applications of 3D printing in the construction industry. This could include developing strategies for the efficient and sustainable production of construction materials, as well as creating innovative designs that take advantage of 3D printing’s capabilities.

By preparing students for a future in which 3D printing is widely used in the construction industry, we can ensure that they are equipped to take advantage of the opportunities that this technology offers. Through a combination of materials education, cross-disciplinary training, and creative problem-solving, students can be given the skills they need to make a real impact in this exciting new field.

Bring Concrete 3D Printing to Your School

For those interested in training students on concrete 3D printing technologies and exposing future minds/leaders to this new reality, TOOLKIT and XtreeE offer a Concrete 3D Printer for Research and Development exactly for this purpose. A cross-collaborative system that allows architecture students to work with construction students, robotics programs, computer science classes, engineering programs and more.

Conclusion

The construction industry is an ever-evolving industry, with new technologies being adopted every few years that promise to revolutionize the way we build. The latest technology to enter the building scene is concrete 3D printing. This new technology is transforming the construction industry by allowing for faster and more efficient construction projects. In this blog post, we will discuss how concrete 3D printing is revolutionizing the construction industry and why it is becoming the go-to technology for many construction projects.