Manufacturing

The need for skilled, qualified, and capable manufacturing workers across the globe, especially here in the US, is one that will continue to rise for the foreseeable future.

Toolkit Technologies is focused on bringing the needed technologies, curriculum, and digital solutions to schools across the country that will train the next generation of manufacturing professionals and leaders.

Our manufacturing training solutions range from integrated mechatronics systems to electrical, sensors, mechanical, fluid power, robotics and more.

Our goal is clear and consistent: to train the future leaders of industry on the leading technologies from industry.

Showing 1–12 of 14 results

-

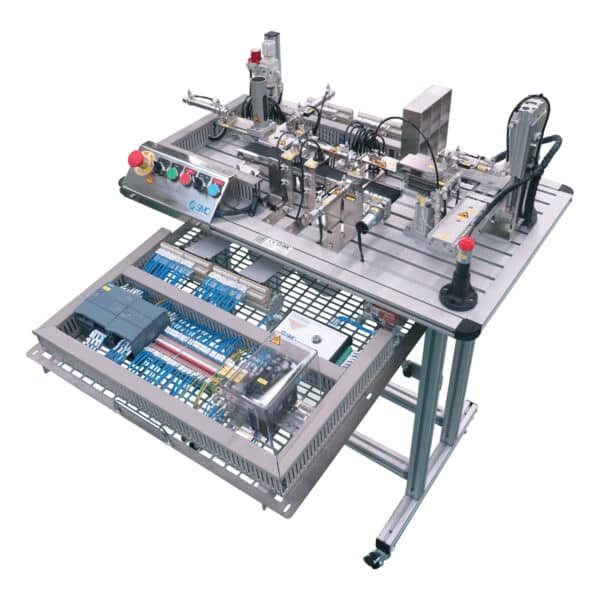

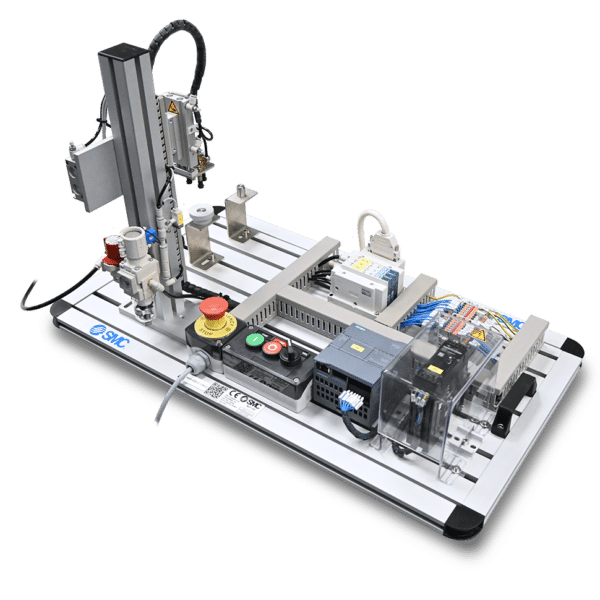

SMC Flexible Manufacturing System – Industry 4.0

The best just got better with this incredible training from SMC! SMC’s FMS-200 Special Edition Industry 4.0 takes the most popular industrial advanced mechatronics training system on the market for mechatronics and industrial troubleshooting training and combines it with advanced Industry 4.0 technologies for real-world, skills-driven training.

The SMC Flexible Manufacturing System is used by countless companies and schools across the globe for real industry training.

-

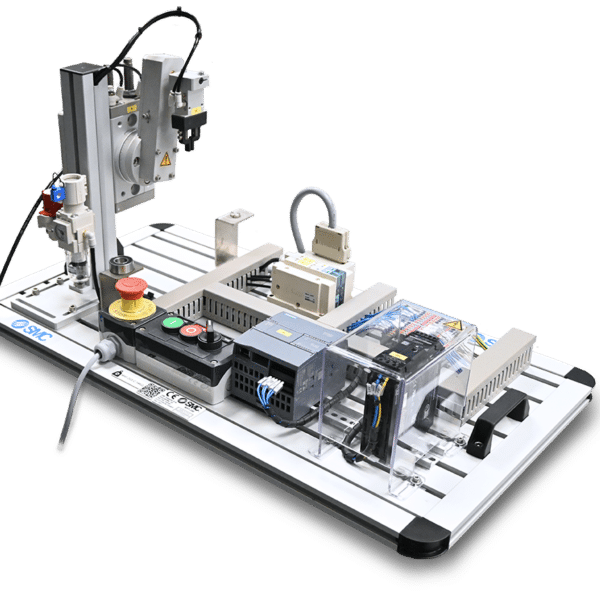

SMC Compact Automation Training System (Automate-200)

SMC’s exciting compact training system for Automation and Mechatronics, AUTOMATE-200, is the perfect training aid for students in advanced manufacturing classrooms for hands-on skills in PLC Programming, Sensors, Pneumatics, Troubleshooting, and More! Developed in partnership with Intel for training in the semiconductor industry, featuring all industrial SMC Components.

-

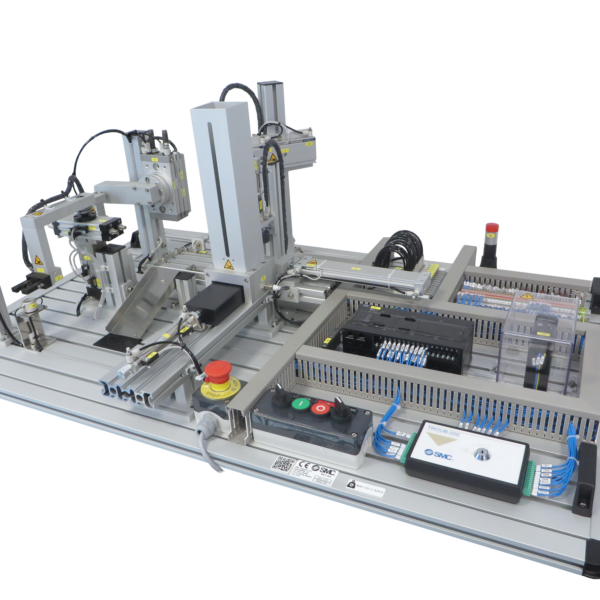

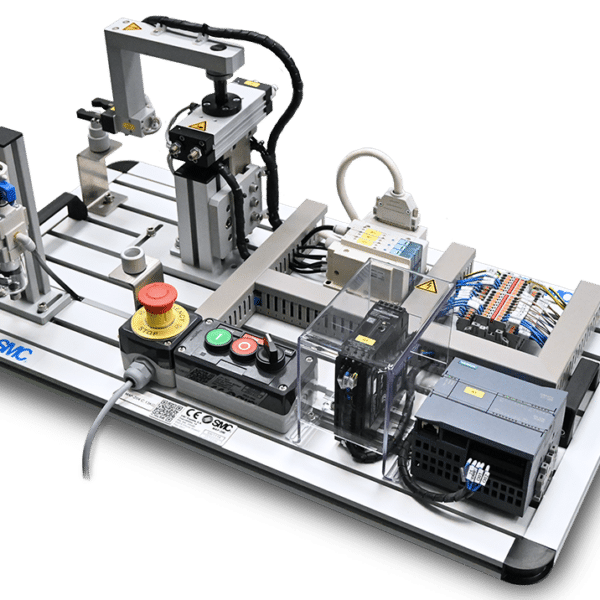

SMC Flexible Assembly System FAS-200

SMC’s FAS-200 Flexible Assembly System is a tried-and-true industrial training system for automation, advanced manufacturing, industrial maintenance, and industrial technology students. Featuring all industrial components and technologies from industry leading manufacturers, the FAS-200 exposes students to industry’s most common technologies with hands-on skills development in pneumatics, hydraulics, PLCs, robotics, troubleshooting, and more!

Customize your modular training system with your choice of Stations, PLCs, Robots, and More!

-

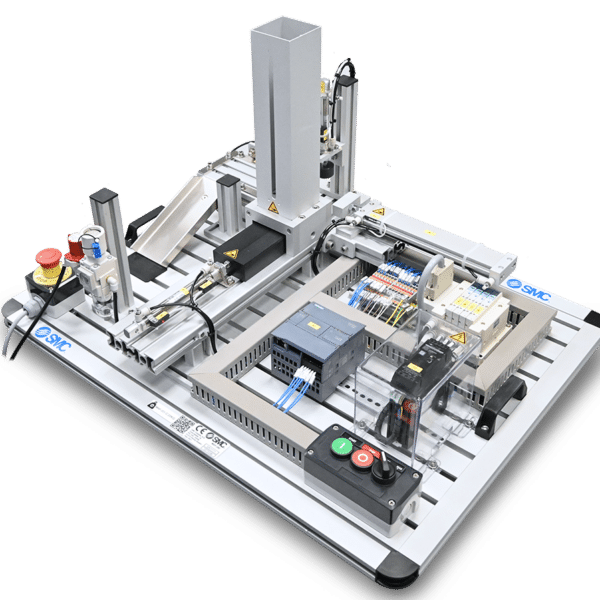

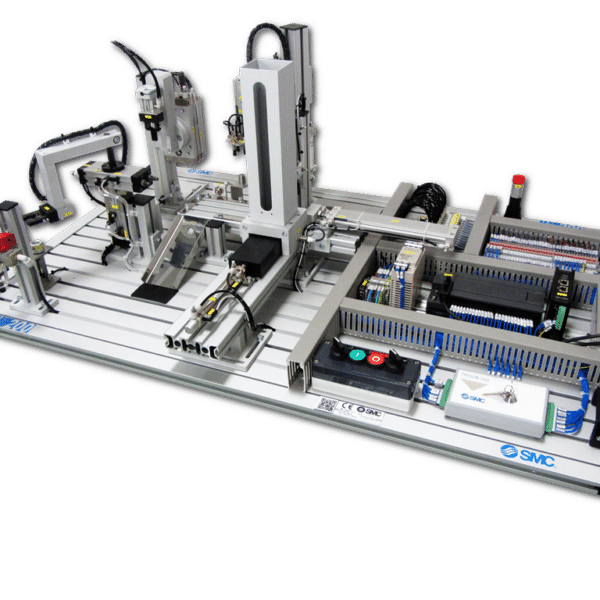

Highly Automated Training System HAS-200

Train your students with the same Industry 4.0 training system used by companies like Intel and Boeing for their workforce training!

The HAS-200 SE i4o brings SMC’s industry leading technologies into a modular, customizable smart factory for education with training options in PLC programming, HMI programming, Management Execution Systems software, interconnected systems, smart devices, robotics, and more.

-

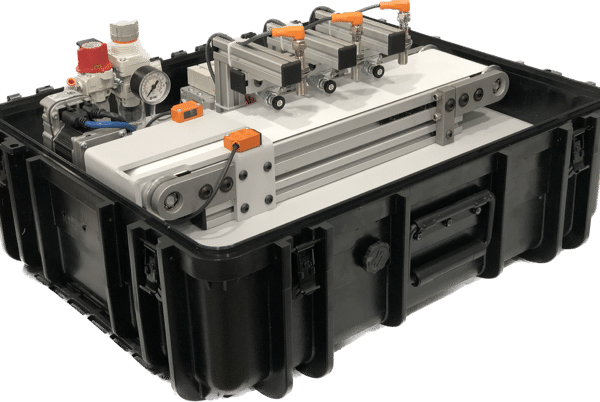

SMC Suitcase Conveyor Training Application

With the SMC PLC Training Applications, students can apply their programming, troubleshooting, and automation skills with real-world, industry-applicable training scenarios.

The Suitcase Conveyor Application allows students to connect the mobile trainer to an external PLC or the SMC PLC Training System (PCT-200) for expanded training opportunities and skills-development.

The conveyor and integrated sensors allow for students to program the PLC to sort and distribute workpieces and parts in an engaging and project-based learning approach.

-

SMC Programmable Logic Controller (PLC) Training System

Take your automation training to the next level with SMC’s Hands-on PLC Training System. With a mobile hard-shell suitcase, this versatile and expandable solution provides the perfect environment to learn about programmable controllers, digital I/O, analog I/O and human machine interfaces (HMIs).

Plus, with two external connection blocks, you can connect any external I/O devices directly to the controller. Get the most out of your training today with SMC’s PLC Training System!

-

SMC Material Handling Training Systems

The MAP-200s consist of a series of individual tabletop mechatronics training systems that carry out a specific and different material handling task commonly seen in industrial settings.

Robust, Rugged, and Versatile, these tabletop hands-on training systems are designed to teach students a wide array of industrial automation – Pneumatics, Electrical, Industrial Safety and Automation Processes, PLC Programming, Sensors, and Troubleshooting!

MAP-201: Body Supply Part Feeder + Detector/Ejector

MAP-202: Vacuum-Held Handling Device with Two Shafts

MAP-203: Vertical Revolving Handling Device with Internal Gripper of Bearing

MAP-204: Horizontal Rotolinear Handling Device with External Gripper of Shaft

MAP-205: Complete Mini-Cell Assembly

-

Part Feeding and Detecting Training System – MAP-201

SMC’s MAP-200s consist of a series of individual tabletop mechatronics training systems that carry out a specific and different material handling task commonly seen in industrial settings.

Robust, Rugged, and Versatile, these tabletop hands-on training systems are designed to teach students a wide array of industrial automation – Pneumatics, Electrical, Industrial Safety and Automation Processes, PLC Programming, Sensors, and Troubleshooting!

MAP-201: Body Supply Part Feeder + Detector/Ejector

The process: A gravity feeder houses the parts in a column. Each part has a non-symmetrical interior housing and is ejected by a pneumatic cylinder. The correct orientation of the part is verified using a cylinder with a plunger. After verification, an oval section pneumatic cylinder moves the work-piece to the final position. Otherwise, a single acting cylinder removes the part via the evacuation ramp.

-

Vacuum-Held Material Handling Training System – MAP-202

SMC’s MAP-200s consist of a series of individual tabletop mechatronics training systems that carry out a specific and different material handling task commonly seen in industrial settings.

Robust, Rugged, and Versatile, these tabletop hands-on training systems are designed to teach students a wide array of industrial automation – Pneumatics, Electrical, Industrial Safety and Automation Processes, PLC Programming, Sensors, and Troubleshooting!

MAP-202: Vacuum-Held Handling Device with Two Shafts

MAP-202: The function of this handling device is to transfer the part from a starting area to a final unloading area, using three vacuum pads. This is a cartesian handling device with two shafts which moves a part from one position to another, holding it with a set of three vacuum pads.

-

Vertical Revolving Material Handling Training System – MAP-203

SMC’s MAP-200s consist of a series of individual tabletop mechatronics training systems that carry out a specific and different material handling task commonly seen in industrial settings.

Robust, Rugged, and Versatile, these tabletop hands-on training systems are designed to teach students a wide array of industrial automation – Pneumatics, Electrical, Industrial Safety and Automation Processes, PLC Programming, Sensors, and Troubleshooting!

MAP-203: Vertical Revolving Handling Training System with Internal Gripper

The function of this material handling device is to transfer the part from a starting area to an unloading area, using an internal gripper. The part used in this process is a bearing so that when it is placed on the unloading area, it fits perfectly onto a stainless steel pivot with a slightly smaller diameter than the bearing’s inner diameter.

-

Horizontal Rotolinear Material Handling Training System – MAP-204

SMC’s MAP-200s consist of a series of individual tabletop mechatronics training systems that carry out a specific and different material handling task commonly seen in industrial settings.

Robust, Rugged, and Versatile, these tabletop hands-on training systems are designed to teach students a wide array of industrial automation – Pneumatics, Electrical, Industrial Safety and Automation Processes, PLC Programming, Sensors, and Troubleshooting!

MAP-204: Vertical Revolving Handling Training System with Internal Gripper

The function of the handling device is to transfer the part from a starting area to an unloading area through a rotolinear actuator that displaces an outer gripper. The part being transported is a metal bearing.

The part used is made from anodized aluminum, 14.6mm diameter and 41mm height, so that when the part is placed on the unloading area it fits perfectly onto a stainless steel pivot with a slightly larger diameter than the shaft.

-

Mini-Cell Material Handling Assembly MAP-205

The MAP-200s consist of a series of individual tabletop mechatronics training systems that carry out a specific and different material handling task commonly seen in industrial settings.

Robust, Rugged, and Versatile, these tabletop hands-on training systems are designed to teach students a wide array of industrial automation – Pneumatics, Electrical, Industrial Safety and Automation Processes, PLC Programming, Sensors, and Troubleshooting!

The MAP-205 combines the MAP-201, MAP-202, MAP-203, and MAP-204 into a single integrated mini-cell assembly.

The MAP-205 assembles and disassembles a product (metal turning mechanism) via 4 handling devices working together on a single tabletop frame.

- Feeding the base

- Assembling the bearing

- Inserting the shaft

- Placing the lid