Sensors

Simply put, Industrial Automation Sensors are input devices which provide an output (signal) with respect to a specific physical quantity (input).

Sensors are vitally important to all major industries and pathways, and TOOLKIT is here to help prepare students in learning these foundational skills.

From standalone training systems solely dedicated to sensors technology and exploration to integrated systems utilizing sensors to their full capabilities, we have the industry-relevant training system to help your students master these important technologies and skills.

Showing 1–12 of 14 results

-

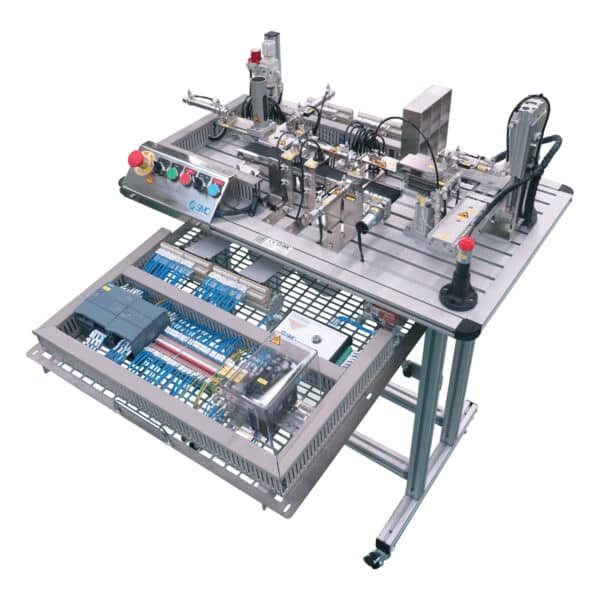

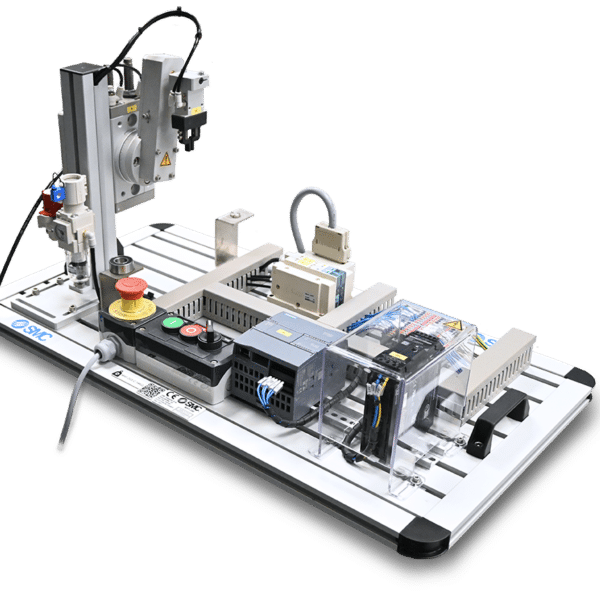

SMC Compact Automation Training System (Automate-200)

SMC’s exciting compact training system for Automation and Mechatronics, AUTOMATE-200, is the perfect training aid for students in advanced manufacturing classrooms for hands-on skills in PLC Programming, Sensors, Pneumatics, Troubleshooting, and More! Developed in partnership with Intel for training in the semiconductor industry, featuring all industrial SMC Components.

-

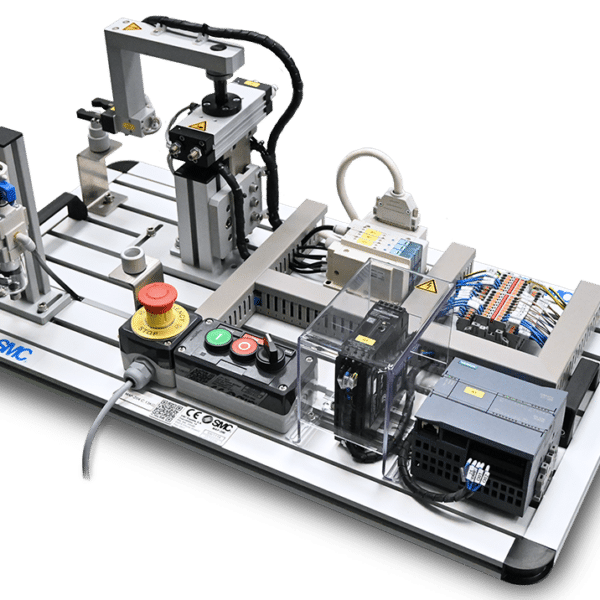

SMC Material Handling Training Systems

The MAP-200s consist of a series of individual tabletop mechatronics training systems that carry out a specific and different material handling task commonly seen in industrial settings.

Robust, Rugged, and Versatile, these tabletop hands-on training systems are designed to teach students a wide array of industrial automation – Pneumatics, Electrical, Industrial Safety and Automation Processes, PLC Programming, Sensors, and Troubleshooting!

MAP-201: Body Supply Part Feeder + Detector/Ejector

MAP-202: Vacuum-Held Handling Device with Two Shafts

MAP-203: Vertical Revolving Handling Device with Internal Gripper of Bearing

MAP-204: Horizontal Rotolinear Handling Device with External Gripper of Shaft

MAP-205: Complete Mini-Cell Assembly

-

SMC Smart Sensors Training System

The SMC SENSOTRAINER-200 is the sensor technology trainer that allows students to learn the different sensors used in industry, such as inductive, capacitive, optical, and fiber optics.

The SENSOTRAINER-200 training system is a platform for exploratory exercises in the topic of digital, analog and smart sensor technologies – all commonly found in various industrial settings. The system easily connects to the SMC PLC Training System for expanded learning.

This system offers an easy connection and flexibility for changing position and orientation in order to explore how the signal is performing.

-

Part Feeding and Detecting Training System – MAP-201

SMC’s MAP-200s consist of a series of individual tabletop mechatronics training systems that carry out a specific and different material handling task commonly seen in industrial settings.

Robust, Rugged, and Versatile, these tabletop hands-on training systems are designed to teach students a wide array of industrial automation – Pneumatics, Electrical, Industrial Safety and Automation Processes, PLC Programming, Sensors, and Troubleshooting!

MAP-201: Body Supply Part Feeder + Detector/Ejector

The process: A gravity feeder houses the parts in a column. Each part has a non-symmetrical interior housing and is ejected by a pneumatic cylinder. The correct orientation of the part is verified using a cylinder with a plunger. After verification, an oval section pneumatic cylinder moves the work-piece to the final position. Otherwise, a single acting cylinder removes the part via the evacuation ramp.

-

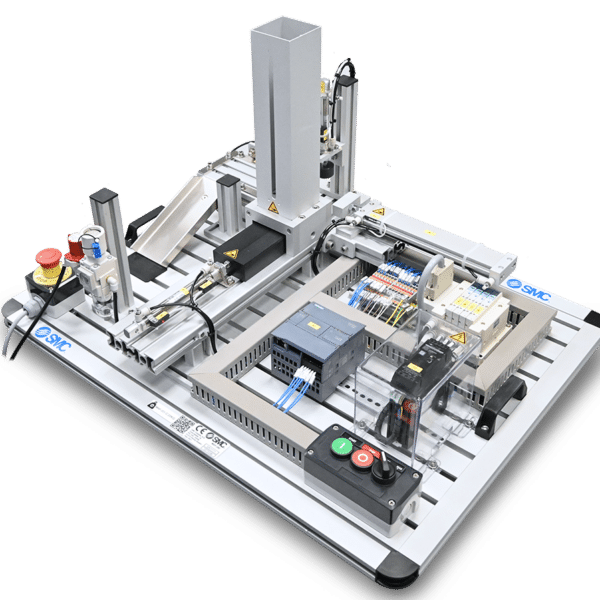

Vacuum-Held Material Handling Training System – MAP-202

SMC’s MAP-200s consist of a series of individual tabletop mechatronics training systems that carry out a specific and different material handling task commonly seen in industrial settings.

Robust, Rugged, and Versatile, these tabletop hands-on training systems are designed to teach students a wide array of industrial automation – Pneumatics, Electrical, Industrial Safety and Automation Processes, PLC Programming, Sensors, and Troubleshooting!

MAP-202: Vacuum-Held Handling Device with Two Shafts

MAP-202: The function of this handling device is to transfer the part from a starting area to a final unloading area, using three vacuum pads. This is a cartesian handling device with two shafts which moves a part from one position to another, holding it with a set of three vacuum pads.

-

Vertical Revolving Material Handling Training System – MAP-203

SMC’s MAP-200s consist of a series of individual tabletop mechatronics training systems that carry out a specific and different material handling task commonly seen in industrial settings.

Robust, Rugged, and Versatile, these tabletop hands-on training systems are designed to teach students a wide array of industrial automation – Pneumatics, Electrical, Industrial Safety and Automation Processes, PLC Programming, Sensors, and Troubleshooting!

MAP-203: Vertical Revolving Handling Training System with Internal Gripper

The function of this material handling device is to transfer the part from a starting area to an unloading area, using an internal gripper. The part used in this process is a bearing so that when it is placed on the unloading area, it fits perfectly onto a stainless steel pivot with a slightly smaller diameter than the bearing’s inner diameter.

-

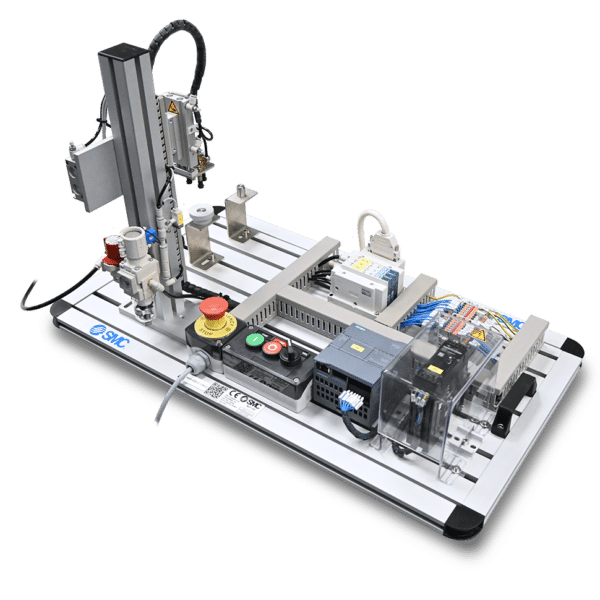

Horizontal Rotolinear Material Handling Training System – MAP-204

SMC’s MAP-200s consist of a series of individual tabletop mechatronics training systems that carry out a specific and different material handling task commonly seen in industrial settings.

Robust, Rugged, and Versatile, these tabletop hands-on training systems are designed to teach students a wide array of industrial automation – Pneumatics, Electrical, Industrial Safety and Automation Processes, PLC Programming, Sensors, and Troubleshooting!

MAP-204: Vertical Revolving Handling Training System with Internal Gripper

The function of the handling device is to transfer the part from a starting area to an unloading area through a rotolinear actuator that displaces an outer gripper. The part being transported is a metal bearing.

The part used is made from anodized aluminum, 14.6mm diameter and 41mm height, so that when the part is placed on the unloading area it fits perfectly onto a stainless steel pivot with a slightly larger diameter than the shaft.

-

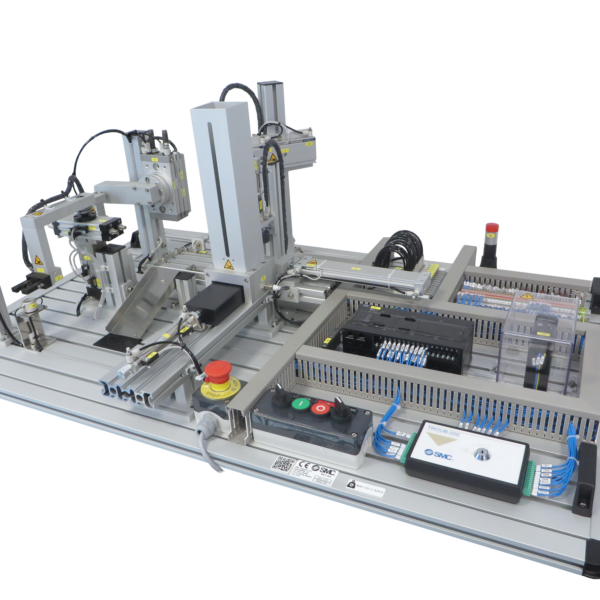

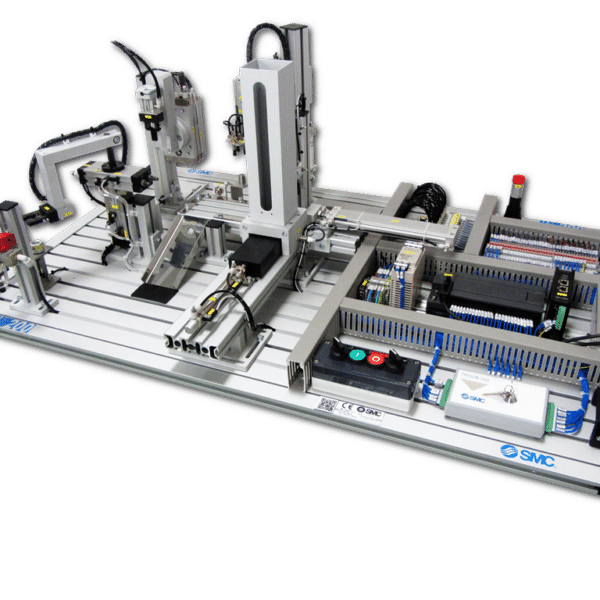

Mini-Cell Material Handling Assembly MAP-205

The MAP-200s consist of a series of individual tabletop mechatronics training systems that carry out a specific and different material handling task commonly seen in industrial settings.

Robust, Rugged, and Versatile, these tabletop hands-on training systems are designed to teach students a wide array of industrial automation – Pneumatics, Electrical, Industrial Safety and Automation Processes, PLC Programming, Sensors, and Troubleshooting!

The MAP-205 combines the MAP-201, MAP-202, MAP-203, and MAP-204 into a single integrated mini-cell assembly.

The MAP-205 assembles and disassembles a product (metal turning mechanism) via 4 handling devices working together on a single tabletop frame.

- Feeding the base

- Assembling the bearing

- Inserting the shaft

- Placing the lid

-

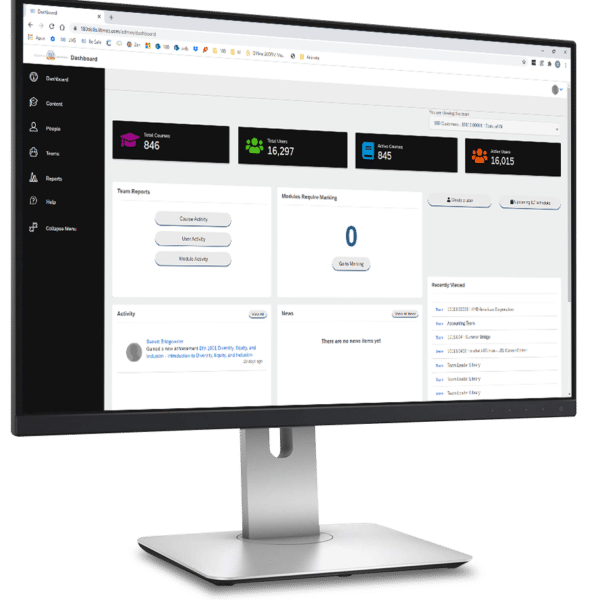

CTE + Workforce eLearning

Toolkit is proud to partner with Valor, 180 Skills, and SMC to bring you the most complete, thorough, and comprehensive eLearning solution for Career and Technical Education. An AWARD-WINNING Learning System for CTE, Workforce Development, and Industry Training.

Web-based eLearning content in over 900 courses – ranging from Career and Technical Education skills, Workforce Development training, Soft Skills development, and more!

Our new eLearning is the most comprehensive skills-based training program out there for real-world skills, certifications, and job-ready outcomes.

Over 600 Technical Skills Courses!

Over 200 Employability and Soft Skills Courses!

Over 80 Quality + Compliance Skills Courses!

-

SMC eLearning

SMC eLEARNING-200 is a flexible, web-based learning platform for skills-based, industry-driven learning to take place anywhere, anytime there is the motivation to learn!

Users can develop skills and theoretical knowledge around Automation and Technical topics such as Robotics, PLCs, Electrical, Pneumatics, Hydraulics, Motors, Sensors and More.

-

SMCTwin-400 Digital Twin Software

We are thrilled to bring the first Digital Twin training software to schools across the globe with SMC’s revolutionary Digital Twin-400 software.

SMCTwin-400 is an online, one-for-one emulation platform where students will be able to develop and control digital twin models. All models operate and behave in the exact manner in which they would in the real world, giving students a never-before-seen lens to view automation and industry.

This true Industry 4.0 software provides students with the ability to access virtual replicas of real SMC training equipment and industrial components, allowing them to safely experience industrial technologies and processes, monitor all of the system’s electrical and pneumatic values, program and create various PLC/HMI programs, and witness the results in real time!

-

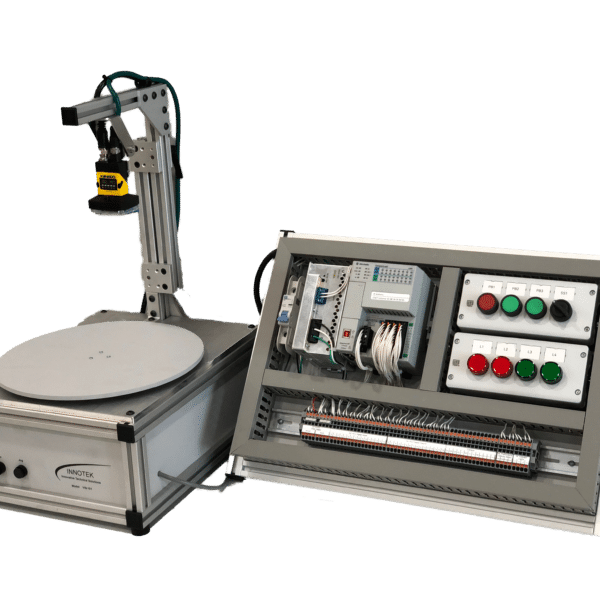

Artificial Vision Training System

Toolkit’s VIS-101 Artificial Vision Training System provides a hardware training solution for introducing the fundamentals of artificial vision to students in mechatronics, automation, robotics, and industrial technology training programs.

The hands-on training system provides components that are used in common industrial applications, allowing participants to perform experiments in camera installation, electrical connections, and configuration of vision jobs via included software.

This Artificial Vision Training System will teach fundamental concepts around artificial vision cameras and technology and will then empower students to take their newly acquired skills to more complex tasks or apply to integrated systems.