Fluid Power

Fluid Power technology is the often-overlooked workhorse behind modern manufacturing and automation of all kinds. Toolkit is proud to bring industry-standard technologies from global leading manufacturers into students’ hands with our remarkable Fluid Power Training Systems.

What is Fluid Power?

Encapsulating both hydraulics and pneumatics, fluid power leverages fluids (or air) under pressure to generate, control, and transmit power from one location to another.

Fluid power systems easily produce linear motion using hydraulic or pneumatic cylinders, whereas electrical and mechanical methods usually must use a mechanical device to convert rotational motion to linear.

Why Fluid Power Training?

Understand fluid power, controlling it, and troubleshooting fluid power circuits is vital to careers in many industrial segments – Manufacturing and Advanced Manufacturing, Heavy Truck and Agriculture Mechanics, Alternative Energy and More.

Did you know that fluid power technologies surround us everyday? Some example of this include: gas pumps; car brakes, dishwashers, airplanes, elevators, amusement park rides, office chairs, and more!

Fluid Power Training Outcomes

With Toolkit, we bring countless years experience as industry leaders into the classroom, with best-in-class fluid power training systems, curriculum, and digital simulation solutions to provide your students with the best hands-on skills training available. Validating student competencies, providing lifelong skills, and empowering students through industry certification.

Industry Skills

Our goal is to empower student success in the workforce through hands-on skills development in topics such as:

– Pneumatics and Electropneumatics

– Pneumatic Directional Control Valve Applications

– Maintenance and Servicing Pneumatic Components

– Air Logic

– Cylinder Loads and Pneumatic Motor Loads

– Component Sizing

Showing all 3 results

-

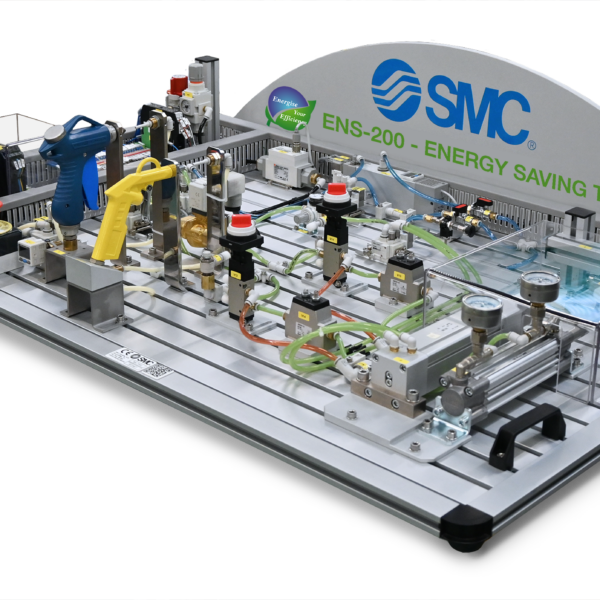

SMC Air Energy Savings Trainer

SMC, the worldwide leading manufacturer of Pneumatic Components and Technologies, has developed a state-of-the-art training system for teaching students about Sustainability, Energy Efficiency, Green Technologies, and Air Leakage.

The ENS-200 integrates a series of applications (vacuum, actuators and blowing) aimed at getting technicians to understand and implement the proper procedures and standards associated with energy saving in compressed air installations.

Modern Manufacturing needs to be green and companies are adopting these green energy conservation technologies and techniques, so let’s train students to be prepared.

The ENS-200 teaches you how to detect possible excessive consumption and suggest actions to prevent it. Users will analyze different scenarios through a series of guided activities. Each experiment shows how much has been saved, both as a percentage and in the chosen currency.

-

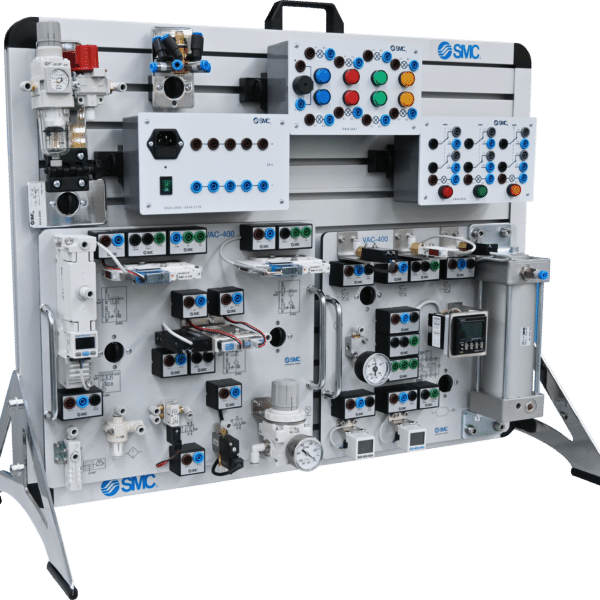

SMC Vacuum Technology Training System

SMC, the worldwide leading manufacturer of Pneumatic Components and Technologies, has developed a training system specifically for hands-on skills development in Vacuum Technology. Featuring the most commonly found vacuum technologies found in industrial companies like Intel, Dell, Apple, Samsung, Toyota, and more, the VAC-400 is the training system needed for skills development training in vacuum technologies.

-

SMCTwin-400 Digital Twin Software

We are thrilled to bring the first Digital Twin training software to schools across the globe with SMC’s revolutionary Digital Twin-400 software.

SMCTwin-400 is an online, one-for-one emulation platform where students will be able to develop and control digital twin models. All models operate and behave in the exact manner in which they would in the real world, giving students a never-before-seen lens to view automation and industry.

This true Industry 4.0 software provides students with the ability to access virtual replicas of real SMC training equipment and industrial components, allowing them to safely experience industrial technologies and processes, monitor all of the system’s electrical and pneumatic values, program and create various PLC/HMI programs, and witness the results in real time!