Industry 4.0

With so much noise around Industry 4.0 and contradicting definitions from one person to the next, it’s no surprise to see why so many schools and teachers don’t know where to begin in training students in the classroom. Toolkit is proud to be the undisputed leader in providing schools and industry professionals Industry 4.0 Training Solutions.

How does one identify the important topics and skills to cover in the classroom when there are so many areas and directions one could take?

Toolkit is here to help with this. Lean on us as you prepare your students for the 4th Industrial Revolution, and we will guide you with the industry’s most intuitive and most robust portfolio of Industry 4.0 training solutions on the market.

From smart devices, IO-link, collaborative and industrial robots, networking and communication protocols, mobile robots, Management Execution Softwares, Predictive Maintenance, Cybersecurity, Data Analytics and more – training for a rapidly digitalizing and changing manufacturing world can be a daunting challenge.

History of i4o

The Fourth Industrial Revolution (Industry 4.0) is a term for the current state of digital expansion seen across the globe and within every industry. It’s a new era that builds on and extends the impact of digitization in new and unanticipated ways. Industry 4.0 has been made possible by digitizing and automating the computerization of previous industrial revolutions through autonomous, cyber-physical systems and machine learning. Rapid disruptive advances in technology like artificial intelligence, robotics, blockchain, and 3D printing have created uncertainty and fear of increased unemployment and inequality.

Recent studies from McKinsey estimate that nearly 375 million workers may need to switch occupational categories as a result of the Industry 4.0. For advanced economies, up to one-third of the 2030 workforce in the United States and Germany, and nearly half in Japan may need to learn new skills and find other occupations. Jobs are not as cut and dry as they once were; most occupations require a set of varied skills and tasks. But rather than being replaced by robots, many jobs will see an increase in the amount of tasks which can be automated.

In fact, McKinsey found that less than 5% of global occupations can be replaced by automation. However, in about 60% of occupations, about a third of associated tasks could be automated, causing workers to either find new jobs or upgrade skills to meet demands.

Automation and Jobs

The low-skilled, repetitive jobs that are at highest risk for replacement through automation will also require new high-skilled positions focused on management, quality control, and require increased supervision. Cost savings in production could, in theory, be translated to reduced product price and thus increased demand, actually helping the economy. Which could potentially increase demand for partly automated occupations.

Toolkit prides itself on providing learners with the Industry 4.0 cyber physical training systems and certifications to prepare the next generation of the workforce.

Showing all 3 results

-

SMC Robot Training System RTS-200

SMC is proud to bring this one-of-a-kind Robot Training Platform to schools for real world robot training!

The RTS-200 training system provides participants with a hardware platform for performing hands-on development for robotic operations. The mobile platform includes various applications which can be quickly installed to provide advanced activities, expanding the learning objectives beyond simple pick and place functions. The design allows participants to advance from basic programming to integration of various technologies including electrical controls, pneumatics, controllers, artificial vision, sensors and more – all with simple drop-in training panels.

Have multiple robots? The RTS-200 allows for multiple robot models and brands to be dropped in as well!

SMC’s Partnership with Universal Robots allows students to get real-world certification on Universal Robots!

-

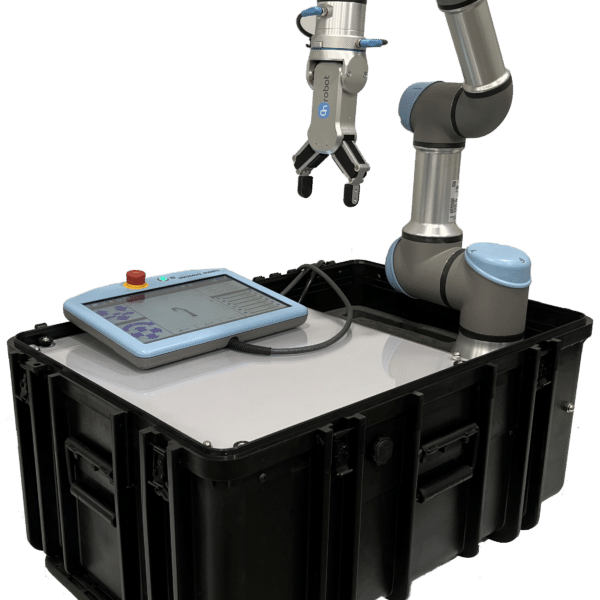

Universal Robot Suitcase Robot Training System

Toolkit Technologies is proud to bring this one-of-a-kind Robot Training Platform to schools for real world robot training!

The RTS-100 combines the modularity and industrial training capabilities of our RTS-200 Robot Training Cart with the advantages of a portable and compact, rugged suitcase form factor. This allows for easy and safe transport to remote training locations, satellite campuses, recruiting events and more. Additionally, the rugged and compact storage case allows for your robot training systems to be easily stored when not in use. Classrooms limited on space particularly enjoy the compact footprint of the RTS-100.

Toolkit’s Portable Robot Training System includes the controller, workpieces, training activities, curriculum, and all required components for successful robotics training. Foam inserts allow for safe and organized storage for all components and workpieces.

The RTS-100 is a great choice for providing industrial training activities around the Universal Robot UR3e, while giving you the flexibility and redeployment advantages of a mobile and portable training system. Reach out for alternative robot options such as Mecademic, uFactory, and more!

-

Robotized Assembly System

SMC’s Robotized Assembly Training System, the RAS-400, allows learners to get a real-world look at fully automated assembly environments featuring your choice of industrial robot(s).

This modular robotized assembly system consists of 4 different industrial robot stations forming a flexible automation cell. The process includes an entire series of

- Feeding

- Material handling

- Assembly verification

- Loading operations

All operations are carried out using components from different technologies (pneumatics, vacuum, sensors, etc.) that students will have to understand and apply. The primary training focus of this training system is industrial robotics, including collaborative robots.