Automotive Technology

Explore Toolkit’s solutions for Automotive Technology Training Systems for modern automotive classrooms.

The ever-increasing quantity of technologies found in modern vehicles, combined with the ever-increasing complexity of electronic systems and state-of-the-art technologies such as Advanced Driver Assistance Systems (ADAS), Smart Sensors, Autonomous Driving systems, Interconnected Systems, Computerized Diagnostic and Scan Tools, Plug-In Electric Vehicle and Hybrid technologies, etc. creates an increased need for automotive training to be done with modern, state-of-the-art technologies and training systems.

Modern Automotive Training Labs should keep pace with modern automotive vehicles on the road.

Automotive service technicians and mechanics can be expected to:

- Identify problems, often by using computerized diagnostic equipment

- Plan work procedures, using charts, technical manuals, and experience

- Test parts and systems to ensure that they work properly

- Follow checklists to ensure that all critical parts are examined

- Perform basic care and maintenance, including changing oil, checking fluid levels, and rotating tires

- Repair or replace worn parts, such as brake pads, wheel bearings, and sensors

- Perform repairs to manufacturer and customer specifications

- Explain automotive problems and repairs to clients

Although service technicians work on traditional mechanical systems, such as engines, transmissions, and drivebelts, they also must be familiar with a growing number of electronic systems. Braking, transmission, and steering systems, for example, are controlled primarily by computers and electronic components.

Other integrated electronic systems, such as accident-avoidance sensors, are becoming common as well. In addition, a growing number of technicians are required to work on vehicles that use electricity or alternative fuels, such as ethanol.

Service technicians use many different tools, including computerized diagnostic tools and power tools such as pneumatic wrenches, lathes, welding torches, and jacks and hoists, in addition to common hand tools like wrenches, pliers, and sockets.

Whether for transportation and logistics classrooms, agriculture and mechanics or manufacturing classrooms, Toolkit has the Automotive Service Technology Training Systems and ASE Certification-aligned solutions to fit your area’s industry training needs.

Job Outlook: 69,000 new jobs per year

Average Pay: $46,890

Shop by ASE Category

Showing all 6 results

-

Planetary Gear Set Trainer

The ConsuLab EM-1100 Planetary Gear Set Trainer is a simple planetary gear assembly that consists of 3 primary components: The ring gear (the outer most gear in black), 3 planet gears (green gears) that are housed by a carrier assembly (green circle) and a sun gear (the yellow gear in the center of the gear set). It allows the demonstration of the seven different gear ratios available with the planetary gear set.

-

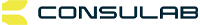

Cutaway Eaton Transmission Trainer

The EC-1108 cutaway Eaton transmission has been designed for teaching Eaton heavy-duty transmission theory and operation. This model provides several forward speeds and reverses, consisting of a front section and an auxiliary section.

The auxiliary section contains LO and HI range ratios, and the L and H splitter gear ratios. When in HI range, the gear ratios can be split by using the splitter control button. This model is driven by hand crank.

-

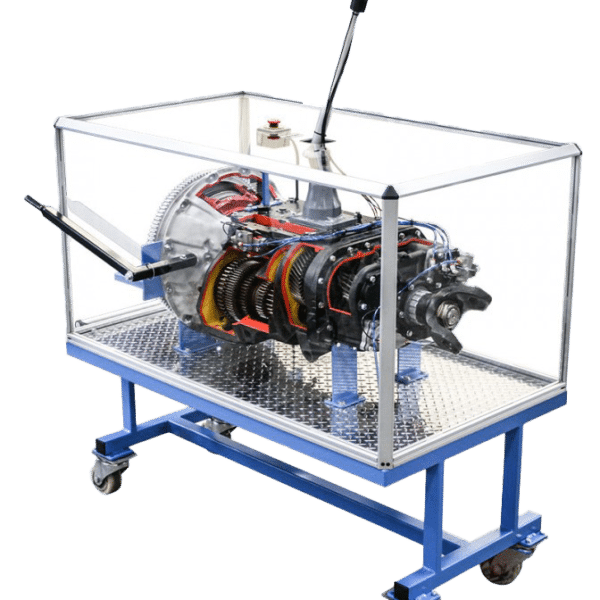

Cutaway Allison Transmission – 3000 SERIES

The ConsuLab EC-1106-03 cutaway Allison transmission has been specifically designed for teaching heavy duty automatic transmission theory and operation. It has been strategically sectioned and cutaway to allow students to visualize the internal transmission functions.

The Allison 3000 series is a fully automatic torque converter driven, electronically controlled 6-speed automatic transmission that is commonly used in coaches and heavy vehicles.

The other Allison Series are available on request.

-

Cutaway Allison Transmission – 1000 SERIES

The ConsuLab EC-1106-01 cutaway Allison transmission has been specifically designed for teaching heavy duty automatic transmission theory and operation. It has been strategically sectioned and cutaway to allow students to visualize the internal transmission functions. The Allison 1000 series is a fully automatic torque converter driven, electronically controlled 5-speed automatic transmission that is commonly used in trucks and light vehicles.

-

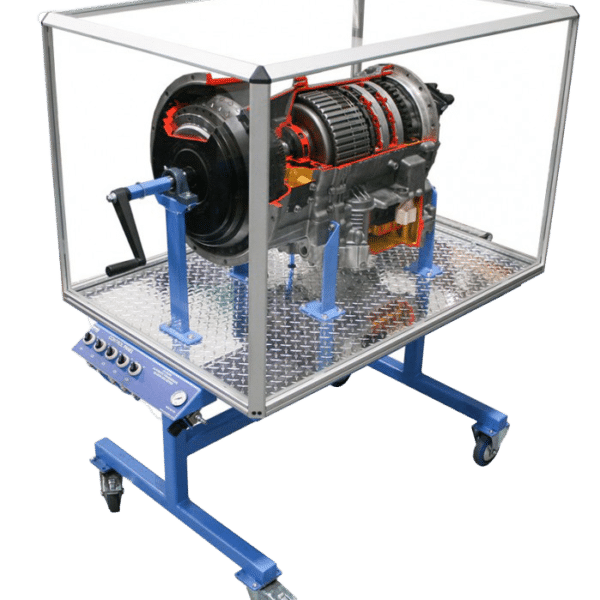

Cutaway Battery

The ConsuLab EC-520 Cutaway Battery is the ideal aid for teaching battery principles and allows visualization of the inner parts. Designed to work in lawn mowers, lawn and garden tractors, small tractors, loaders, backhoes, 4-wheelers, generators, and motorcycles. No electrolyte for educational purposes.

-

Driveshaft Angle Trainer

The ConsuLab Driveshaft Working Angle Trainer EM-200-28 is designed to help demonstrate and simplify the complex acceleration and deceleration phenomenon that occurs in revolving universal joints and drive shafts operating at various angles.

Even when the input driveshaft rotates at constant speed, the output driveshaft maintains a variable speed depending on the angle between them, which causes vibrations and wear over time. The higher the angle between the shafts, the more amplified the effect is.