Automotive Technology

Explore Toolkit’s solutions for Automotive Technology Training Systems for modern automotive classrooms.

The ever-increasing quantity of technologies found in modern vehicles, combined with the ever-increasing complexity of electronic systems and state-of-the-art technologies such as Advanced Driver Assistance Systems (ADAS), Smart Sensors, Autonomous Driving systems, Interconnected Systems, Computerized Diagnostic and Scan Tools, Plug-In Electric Vehicle and Hybrid technologies, etc. creates an increased need for automotive training to be done with modern, state-of-the-art technologies and training systems.

Modern Automotive Training Labs should keep pace with modern automotive vehicles on the road.

Automotive service technicians and mechanics can be expected to:

- Identify problems, often by using computerized diagnostic equipment

- Plan work procedures, using charts, technical manuals, and experience

- Test parts and systems to ensure that they work properly

- Follow checklists to ensure that all critical parts are examined

- Perform basic care and maintenance, including changing oil, checking fluid levels, and rotating tires

- Repair or replace worn parts, such as brake pads, wheel bearings, and sensors

- Perform repairs to manufacturer and customer specifications

- Explain automotive problems and repairs to clients

Although service technicians work on traditional mechanical systems, such as engines, transmissions, and drivebelts, they also must be familiar with a growing number of electronic systems. Braking, transmission, and steering systems, for example, are controlled primarily by computers and electronic components.

Other integrated electronic systems, such as accident-avoidance sensors, are becoming common as well. In addition, a growing number of technicians are required to work on vehicles that use electricity or alternative fuels, such as ethanol.

Service technicians use many different tools, including computerized diagnostic tools and power tools such as pneumatic wrenches, lathes, welding torches, and jacks and hoists, in addition to common hand tools like wrenches, pliers, and sockets.

Whether for transportation and logistics classrooms, agriculture and mechanics or manufacturing classrooms, Toolkit has the Automotive Service Technology Training Systems and ASE Certification-aligned solutions to fit your area’s industry training needs.

Job Outlook: 69,000 new jobs per year

Average Pay: $46,890

Shop by ASE Category

Showing all 4 results

-

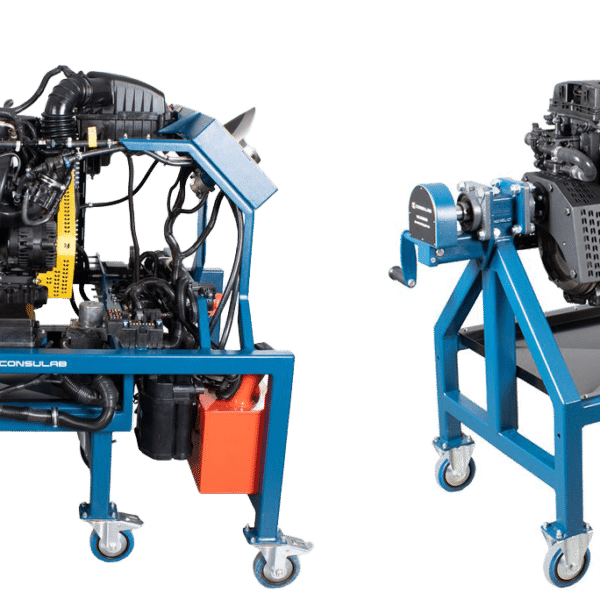

Cutaway Starting System Trainer

The ConsuLab EM-200-19 Starting System Trainer allows for the demonstration of a complete starting system using real-world components. Key areas of the starter have been cutaway to allow visual observation of major components while still being functional.

-

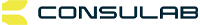

Engine Training Stand with Starting Station and 1.8L GM Chevy

The ConsuLab EM-145S-GM05 Engine Trainer with GM Chevy Sonic Ecotec engine on a swivel stand is designed for student instruction and practice covering engine mechanical inspection, disassembly, measurement and reassembly.

The working engine training system is securely mounted to a heavy duty rotating device equipped with an automatic lock to allow full 360 degree rotation. A steel mounting plate is used for engine mounting that allows full access for rear main seal and flywheel service. Each engine comes equipped with a transmission flywheel (manual or automatic).

The engine starting station contains all components and systems necessary for the starting and running of the Ecotec engine. All necessary engine systems connections are provided to allow live operation of each swivel engine stand.

-

Engine Mechanical Diagnostics Trainer

The ConsuLab EM-141S-TY01 Automotive Training Aid is a working engine trainer for teaching engine mechanical diagnosis on a Toyota Corolla platform. The EM-141S-TY01 Mechanical Diagnosis Engine trainer was designed for the purposes of teaching students mechanical engine component failure diagnosis, and is a real time-saver allowing instructors to instantly provide a “turn-key” engine mechanical fault diagnosis package.

Have you ever wanted a running engine with repeatable mechanical faults that all of your students could diagnose? Would you like an engine system that has internal mechanical faults not requiring you to reinsert and repair them after each student use? Our EM-141S-TY01 does exactly that, and makes teaching automotive technicians easier.

The working engine bench is made to order and comes with complete curriculum and student activity manuals.

-

Cutaway Variable Geometry Turbocharger

Explore the Cutaway of a variable geometry turbocharger based on a Toyota platform.