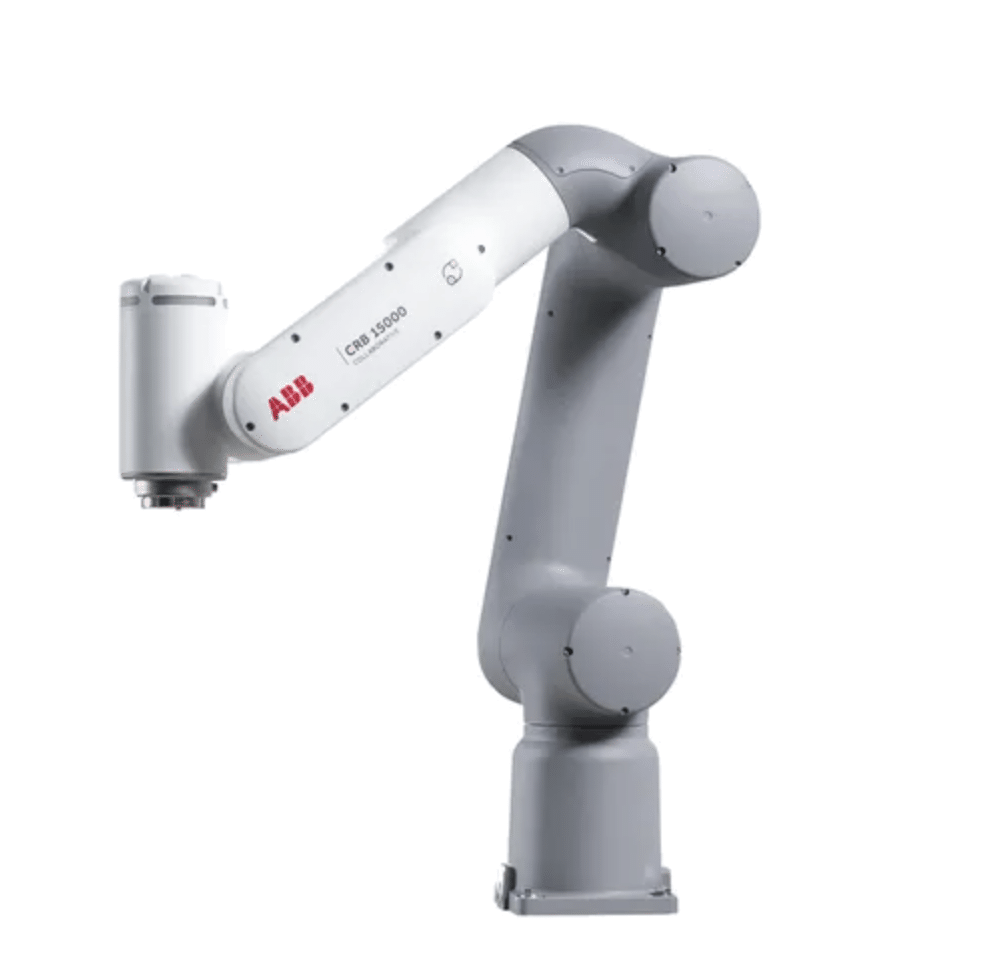

Description

The GoFa CRB 15000 from ABB is possibly the best industrial collaborative robot on the market for both industry and education. Featuring unparalleled user-ability, safety, quality, software, and accessory options – this robot brings endless classroom potential.

- Fundamental Robotics and Automation Training – pick & place, programming, automation principles

- Welding – automated welding

- Machine Tending

- Sanding, Polishing, Buffing

- Injection Molding

- Screwdriving

- Quality Assurance, Quality Control

Greater Productivity

– GoFa offers a maximum Tool Center Point (TCP) speed of up to 2.2 m/s,* faster than other cobots in its class.

– GoFa can perform more operations in a set period than competing robots.

– Another key feature is GoFa’s reach which, at 950mm, outperforms other 5kg cobots by around 12 per cent.

– With a 70 per cent longer reach than ABB’s YuMi single arm robot, GoFa enables loads to be picked up and moved over greater distances, making it an effective solution for a variety of applications, from machine tending and material handling through to packing and packaging.

– With the ability to accurately pick up, move and place objects over greater distances than other robots in its class, GoFa can help to reduce the number of cobots that may be needed in a single space.

Collaborative Safety

– Designed for handling payloads up to 5 kg, GoFa has integrated torque sensors in each of its six joints offering superior power and force limiting performance.

– Together, these prevent the risk of injury by bringing GoFa to an immediate stop if it senses any contact with a human worker.

– Set up and configuration is easy with intuitive, graphical Apps directly on the FlexPendant.

– You can move your robot using lead through in no time.

Specifications

– 5kg payload

– 950mm reach (~37″)

– Max Tool Center Point (TCP) speed up to 2.2 meters per second

– Small footprint, lightweight manipulator and ability to mount in any direction (wall, floor, ceiling mount etc.)

– 6-axis agility

– Standard flange on axis 6

– Cobot label and white/gray color scheme

– Integrated joint design with torque and positioning sensors in each of GoFa’s six joints for superior power and force limiting to offer safe contact with humans

– Interaction status light to communicate cobot status – white (standby)/ green (running production) / yellow (programming) / red (stop).

– SafeMove Configurator app on the ABB FlexPendant.

– Powered by OmniCore™ controller with best-in-class motion control functions.

– PL d certified safety functions built in

– Safety certified PL d Cat 3.

– IP54 protection

– Ease of use: quick calibration and configuration.

– Ease of use: Wizard Easy Programming.

– Ease of use: Lead-through programming by ‘grabbing’ anywhere on the robot.

– Ease of use: Arm-Side Interface (ASI) on axis 6.

– Degrees of freedom: 6 DOF

– Weight: 27kg

– Footprint: 165x165mm