Mechatronics

Mechatronics is the big-strange word that covers so much. The marriage of mechanical, electrical, computer and software skills in order to work with smart technologies, TOOLKIT prepares students for various career pathways within the ever-changing landscape of Mechatronics.

Students learn integrated systems that combine electrical technologies with mechanical technologies and computer programming for real-world skills that directly relate to modern jobs in manufacturing and automation.

Mechatronics sits at the intersection of mechanics, electronics, and computing, and is built on the idea of creating simpler and smarter systems. Toolkit provides the training systems that empower mechatronics technicians and specialists with the skill sets to thrive in contemporary, advanced automated manufacturing industries.

Electro-mechanical technologists and technicians combine knowledge of mechanical technology with knowledge of electrical and electronic circuitry. They operate, test, and maintain unmanned, automated, robotic, and/or electromechanical equipment.

Electro-mechanical and mechatronics technologists and technicians typically do the following:

- Read blueprints, schematics, and diagrams to determine the method and sequence of assembly of a machine or a piece of equipment

- Verify dimensions of parts, using precision measuring instruments

- Operate metalworking machines to make housings, fittings, and fixtures

- Inspect parts for surface defects

- Repair and calibrate hydraulic and pneumatic assemblies

- Use instruments to test the performance of electromechanical assemblies

- Use soldering equipment and hand tools to install electronic parts and hardware

- Operate, test, or maintain robotic equipment

- Analyze and record test results

They install, maintain, and repair automated machinery and computer-controlled mechanical systems in industrial settings, and also test, operate, and/or maintain robotic equipment at worksites. This equipment may include unmanned submarines, aircraft, or similar types of equipment for uses that include oil drilling, deep-ocean exploration, or hazardous-waste removal.

They average pay for someone with these skills is over $61,040.00.

Showing all 11 results

-

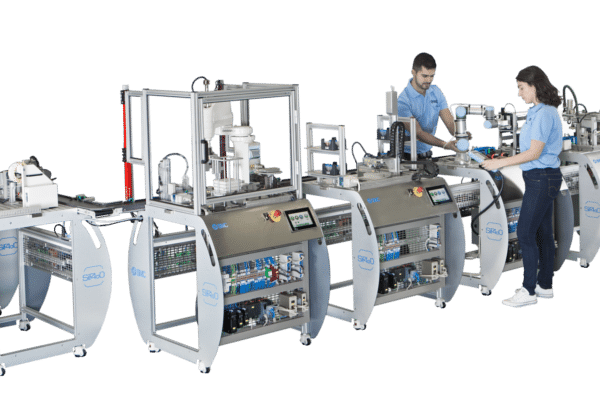

SMC Smart Innovative Factory Training System

Take a look at the most remarkable, fully-connected Industry 4.0 Training Platform on the market for hands-on training, exploration, and research in advanced manufacturing industries: SMC’s SIF-400.

SMC’s Industry 4.0 Smart Innovative Factory reproduces an industrial, cyber-physical smart factory – in both production applications and supply chain applications – for a school to provide real-world advanced manufacturing training. The training system is a modular design comprised of 14 interconnected stations for hands-on training and research of connected systems, operational data and data analytics, IIoT, predictive and preventative maintenance, management execution software (MES), inventory tracking and control, cybersecurity, and more.

This system is aligned with SMC’s Industrial Certification Pathway for Industry 4.0.

-

SMC Mechatronics + Industry 4.0 Learning System (M&I-400)

The newest training system for developing skills in both Mechatronics and Industry 4.0 technologies.

SMC’s M&I-400 is a learning system designed for training on industrial technologies in mechatronics and industry 4.0, while being incredibly attractive and visually appealing. The industrial system makes it easy for students to attain industry’s most needed skills through exciting and practical activities, while also attracting students to learn these skills and technologies.

Projects and activities can be carried out that motivate students to explore Industry 4.0 concepts and technologies while also learning important fundamental concepts related to Mechatronics.

SMC’s M&I-400 emulates a highly automated factory, where different types of products are produced, packed and shipped. The M&I-400 training system makes it possible to work on advanced and connected manufacturing concepts.

This system is aligned with SMC’s Industrial Certification Pathway for Industry 4.0.

-

Compact Industry 4.0 Fundamentals Training System

Training equipment in mechatronics with Industry 4.0 technologies.

Develop the skills most in demand for 4.0 technologies and be prepared for the new challenges presented by Industry 4.0.

The FAS-200 SE I4.0 system offers professional training according to the industrial reality, simulating a real assembly process and including different technologies from Industry 4.0. This system consists of an automated flexible assembly cell with five different stages: Assembly, Handling, Quality Inspection, Transfer, and Warehouse and Shipment.

-

SMC Flexible Manufacturing System – Industry 4.0

The best just got better with this incredible training from SMC! SMC’s FMS-200 Special Edition Industry 4.0 takes the most popular industrial advanced mechatronics training system on the market for mechatronics and industrial troubleshooting training and combines it with advanced Industry 4.0 technologies for real-world, skills-driven training.

The SMC Flexible Manufacturing System is used by countless companies and schools across the globe for real industry training.

-

SMC Flexible Assembly System FAS-200

SMC’s FAS-200 Flexible Assembly System is a tried-and-true industrial training system for automation, advanced manufacturing, industrial maintenance, and industrial technology students. Featuring all industrial components and technologies from industry leading manufacturers, the FAS-200 exposes students to industry’s most common technologies with hands-on skills development in pneumatics, hydraulics, PLCs, robotics, troubleshooting, and more!

Customize your modular training system with your choice of Stations, PLCs, Robots, and More!

-

Highly Automated Training System HAS-200

Train your students with the same Industry 4.0 training system used by companies like Intel and Boeing for their workforce training!

The HAS-200 SE i4o brings SMC’s industry leading technologies into a modular, customizable smart factory for education with training options in PLC programming, HMI programming, Management Execution Systems software, interconnected systems, smart devices, robotics, and more.

-

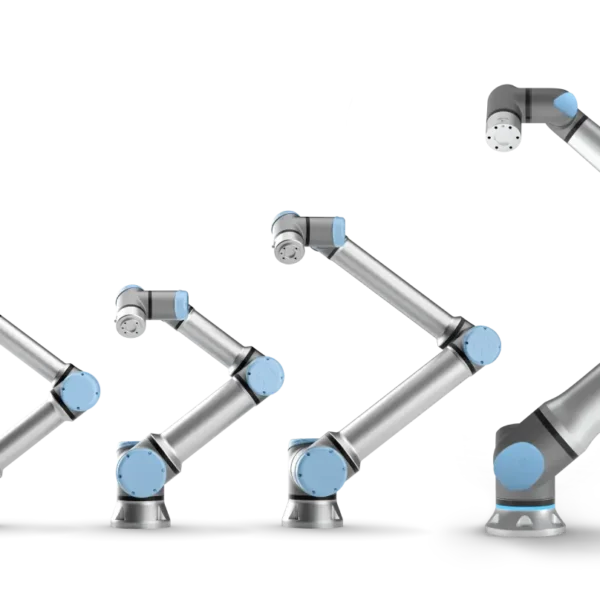

Universal Robots Collaborative Robots

Toolkit Technologies is proud to offer Universal Robots’ industry-leading collaborative robots to education and training institutions around the country.

Empower your students with cutting-edge industrial skills training solutions using Universal Robots’ collaborative robots. Our hands-on training systems, featuring all-industrial technologies sourced from industry leaders like SMC, UR, Miller Electric, and others, immerse learners in real-world applications that prepare them for dynamic careers in today’s tech-driven workforce.

Elevate your educational programs with our state-of-the-art robotics technology, fostering innovation and expertise in your students. Explore our range of training solutions now for comprehensive technical education solutions that drive future success.

We are proud to offer robust curriculum, eLearning, on-site training, and custom training applications with every UR Robot.

Let us know what robotics application you want to teach, and we’ll build it!

-

Conveyor and Logistics Automation Training System

The Conveyor and Logistics Automation Training System with Troubleshooting is our industrial training solution for school and companies looking for practical and realistic hands-on training activities in areas such as Maintenance, Troubleshooting, and Programming of industrial automation technologies commonly seen in warehouses, logistics settings, and industrial automation factories.

The mobile and modular system includes choices of PLC controller, Variable Frequency Drive, HMI’s, and conveyors. Conveyors stations can include: flatbed slider belt conveyors, roller bed belt conveyors, powered roller conveyor, plastic mesh conveyor, and more.

Up to 32 Troubleshooting Faults can be incorporated so students can troubleshoot and repair faulted components.

-

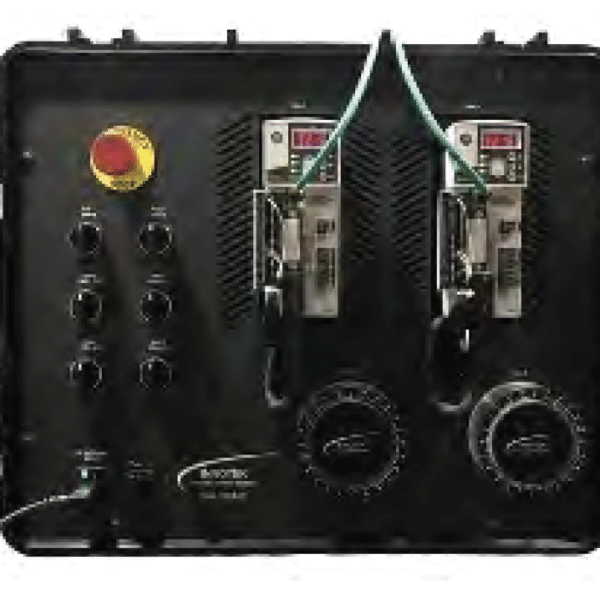

Servo (Drives) Motion Training System

The Servo Motion Training System provides participants with hardware allowing for hands-on experiments in setup,

configuration and programming and servo drives for rotary or linear motion. The system gives access to onboard input and

output devices in addition to providing connectivity for external devices.

The system can be purchased with a Motion-Capable PLC or utilized in combination with an existing motion-capable PLC.

Tabletop or Suitcase Form Factor

- 120Vac Power Entry

- Emergency Stop

- (3) Selector Switches (Enable, + Over-Travel, – Over-Travel)

- (2) Homing Sensors

- (2) Servo Rotary Axis

- (2) Servo Drives

-

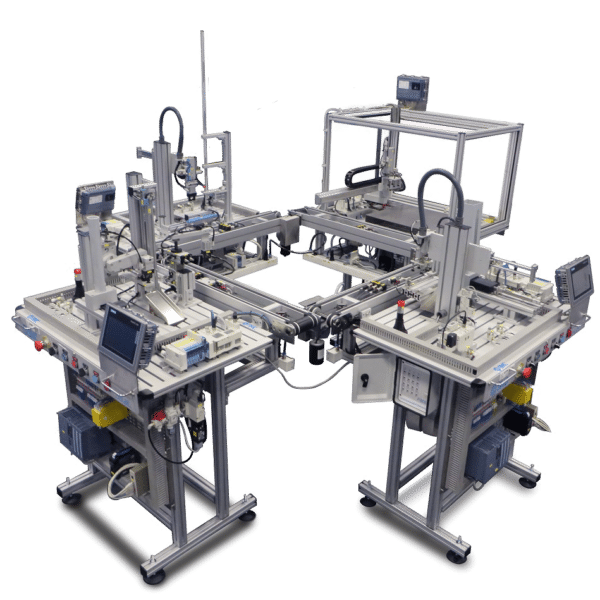

4-Station Flexible Manufacturing System i4o

The best just got better with this incredible training from SMC! The FMS-200 Special Edition Industry 4.0 takes the most popular industrial advanced mechatronics training system on the market and combines it with advanced Industry 4.0 technologies for real-world, skills-driven training for industry.

The 4-Station Configuration brings classrooms a compact and expandable solution for hands-on Industry 4.0 training with built-in troubleshooting.

Students will get industry-relevant hands-on training around the crucial skills demanded by manufacturing and industry. Industrial manufacturing skills student expect to receive include automation processes, safety, PLC programming, Distributed IO, smart devices, artificial vision, and more!

-

Robotized Assembly System

SMC’s Robotized Assembly Training System, the RAS-400, allows learners to get a real-world look at fully automated assembly environments featuring your choice of industrial robot(s).

This modular robotized assembly system consists of 4 different industrial robot stations forming a flexible automation cell. The process includes an entire series of

- Feeding

- Material handling

- Assembly verification

- Loading operations

All operations are carried out using components from different technologies (pneumatics, vacuum, sensors, etc.) that students will have to understand and apply. The primary training focus of this training system is industrial robotics, including collaborative robots.