Robotics

Robotics classrooms are some of the most exciting classrooms in the schools. Toolkit is proud to bring schools the very best Robotics Training Systems on the market for industry-relevant and fun learning.

Job Outlook

The U.S. Bureau of Labor Statistics (BLS) puts robotics engineers in its category for mechanical engineers. Projections show 9% job market growth, if not more, for the foreseeable future.

Major skills gaps, growing workforce shortages, and increased demand for safe and quality working conditions are only increasing the need and demand for robotics deployment in industry.

Skills Shortage

The need for robotics training at all levels of education is increasingly important. As the demand for robotics increases, and the deployment of robots grows in all sectors of industry, the skills gap grows only wider.

Industry needs well-trained individuals with skills in robotics, troubleshooting, programming, I/O, motor controls, sensors, and critical thinking skills.

Toolkit Robotics Solutions

Our Robotics + Automation training systems bring the exciting fields of industrial automation and robotics to students’ fingertips with real-world, industrially-relevant technologies. Toolkit is proud to offer industry-needed and demanded robot certifications.

We have some of the world’s best and wide-ranging industrial robots, collaborative robots, mobile robots, quadruped ‘dog’ robots, robots for competition, adaptive robot grippers and more!

It wouldn’t be a Toolkit Training System without best-in-class curriculum, digital solutions like simulation software and AR/VR Tools. Ask us today for a free robot consultation!

Showing all 3 results

-

SMC Robot Training System RTS-200

SMC is proud to bring this one-of-a-kind Robot Training Platform to schools for real world robot training!

The RTS-200 training system provides participants with a hardware platform for performing hands-on development for robotic operations. The mobile platform includes various applications which can be quickly installed to provide advanced activities, expanding the learning objectives beyond simple pick and place functions. The design allows participants to advance from basic programming to integration of various technologies including electrical controls, pneumatics, controllers, artificial vision, sensors and more – all with simple drop-in training panels.

Have multiple robots? The RTS-200 allows for multiple robot models and brands to be dropped in as well!

SMC’s Partnership with Universal Robots allows students to get real-world certification on Universal Robots!

-

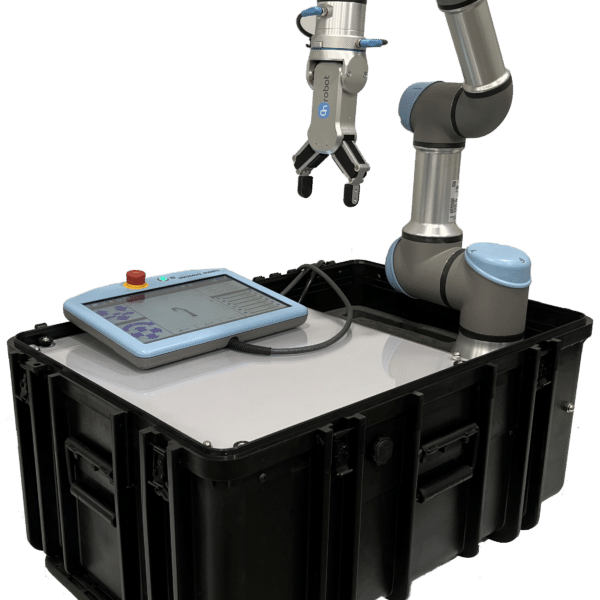

Universal Robot Suitcase Robot Training System

Toolkit Technologies is proud to bring this one-of-a-kind Robot Training Platform to schools for real world robot training!

The RTS-100 combines the modularity and industrial training capabilities of our RTS-200 Robot Training Cart with the advantages of a portable and compact, rugged suitcase form factor. This allows for easy and safe transport to remote training locations, satellite campuses, recruiting events and more. Additionally, the rugged and compact storage case allows for your robot training systems to be easily stored when not in use. Classrooms limited on space particularly enjoy the compact footprint of the RTS-100.

Toolkit’s Portable Robot Training System includes the controller, workpieces, training activities, curriculum, and all required components for successful robotics training. Foam inserts allow for safe and organized storage for all components and workpieces.

The RTS-100 is a great choice for providing industrial training activities around the Universal Robot UR3e, while giving you the flexibility and redeployment advantages of a mobile and portable training system. Reach out for alternative robot options such as Mecademic, uFactory, and more!

-

Robotized Assembly System

SMC’s Robotized Assembly Training System, the RAS-400, allows learners to get a real-world look at fully automated assembly environments featuring your choice of industrial robot(s).

This modular robotized assembly system consists of 4 different industrial robot stations forming a flexible automation cell. The process includes an entire series of

- Feeding

- Material handling

- Assembly verification

- Loading operations

All operations are carried out using components from different technologies (pneumatics, vacuum, sensors, etc.) that students will have to understand and apply. The primary training focus of this training system is industrial robotics, including collaborative robots.