Process Control

Process Control is the ability to monitor and adjust a process to produce a desired output. This may pertain to Advanced Manufacturing industries, Oil and Gas, Instrumentation, Food and Beverage Processing, and More.

TOOLKIT’s Process Control training systems are designed to industrial standards to train students for future careers in these fields, and are complete with simulations, SCADA software and digital solutions to fit your classroom’s industry training needs.

Students will learn skills in monitoring and controlling Process Control such as Pressure, Level, Flow, and Temperature.

Showing all 2 results

-

Lock-Out Tag-Out Training System

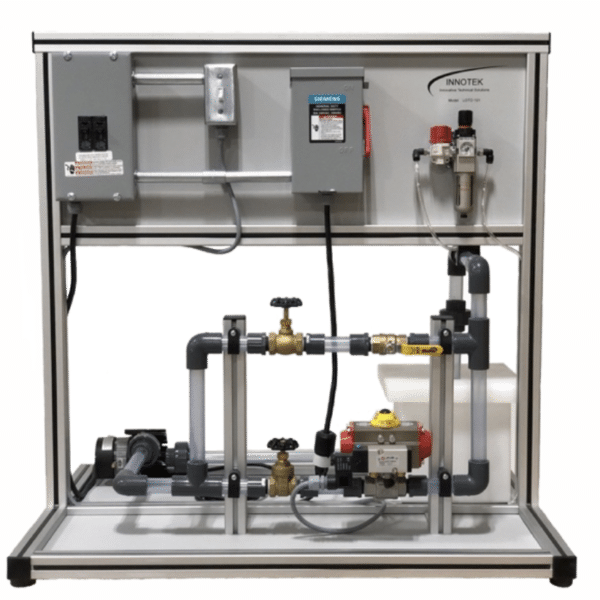

The Innotek Lockout-Tagout Training system provides learners with hardware allowing for demonstration and assessment of LOTO procedures. Lock-Out Tag-Out trainer puts students in the front seat of proper safety procedures in industrial workplaces.

According to the Occupational Safety and Health Administration (OSHA), lock-out/tag-out is one of the Top 10 “”Most Serious Violations”” and “”Most Often Cited Violations”” in industrial workplaces. LOTO must be taken seriously, as lives could be at stake. Workers maintaining equipment can be seriously injured from the unexpected energization of, release of stored energy from, or startup of equipment.

Proper Lock-Out Tag-Out procedures establish standards for the shutdown of equipment, so that energy sources can be isolated to prevent the release of potentially-hazardous energy during routine maintenance activities. Following proper LOTO procedures helps workers to avoid preventable workplace accidents and injuries.

The LOTO-101 training system is a functional system and operates a pump/tank circuit with various power sources and valves for multiple training scenarios. All required safety devices are included with the system for both electrical and mechanical devices.

-

Pumps Training System

The Pumps Training System provides a hardware solution for hands-on training and study in the topic area of pumps and pump characteristics. Students learn how to operate, install, maintain, troubleshoot, analyze performance, and select centrifugal pumps.

The PUMP-200 training system teaches skills related to commonly used pumps in industrial applications, such as centrifugal pumps, which are used in almost every industry to transfer non-hydraulic fluids of various types from one place to another.