Ag Mechanics

Toolkit is proud to offer the very best Ag Mechanics Training Systems for schools and workforce development programs.

The heartbeat of America’s farmland, nothing would be possible in modern agriculture practices with machinery and technicians who know how to operate, fix, repair, and maintain this machinery.

Ag Mechanics Job Outlook

Ag Mechanics refers to the people and technology that helps farmers and ranchers maintain their lands – from building or troubleshooting hydraulic circuits to welding or diagnosing/repairing a diesel engine.

Known as Agricultural Equipment Mechanic, Combine Mechanic, Dairy Equipment Mechanic, Dairy Equipment Repairer, Harvester Mechanic, Irrigation Equipment Mechanic, Milking Machine Mechanic, or Tractor Mechanic.

The overall job outlook for Farm Equipment Mechanic or Service Technician careers has been positive since 2004. Vacancies for this career have increased by 16.09 percent nationwide in that time, with an average growth of 1.01 percent per year. Demand for Farm Equipment Mechanics and Service Technicians is expected to go up, with an expected 5,580 new jobs filled by 2029. This represents an annual increase of 1.74 percent over the next few years

Toolkit is here to bring hands-on and exciting Ag Mechanics Training Systems to CTE classrooms.

Showing 1–12 of 13 results

-

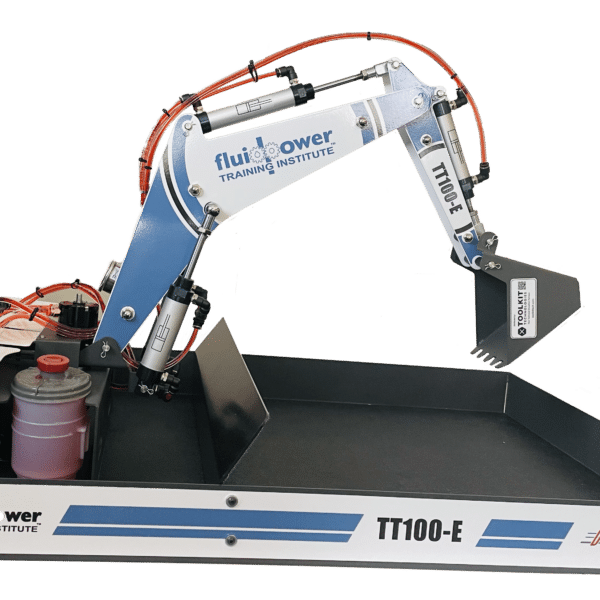

Tabletop Hydraulic Excavator Kit

Our brand new tabletop hydraulics excavator kit brings real-world hydraulic principles to life for students to explore hydraulics in an engaging and project-based approach!

Build your excavator and learn the basic hydraulic concepts necessary for industrial skills in agriculture, industrial maintenance, heavy truck, and manufacturing careers.

Build, Create, Dig, and Learn!

-

MF102 Hydraulics Training System

TOOLKIT is proud to offer the flagship hydraulics training system from the Fluid Power Training Institute (MF102-H), which includes 40-hours of possible training in hydraulics.

From foundational hydraulics skills and safety to advanced hydraulic concepts, this system features unparalleled design, craftsmanship, ergonomics, and robustness perfect for any classroom or training program. Featuring all industrial components, this system is made and manufactured in the USA.

Single-Sided or Double-Sided

-

MF102 Hydraulics Trainer + Troubleshooting

We are proud to bring this incredible hydraulics training system to schools whereby students can get invaluable hands-on training in the fundamentals of Hydraulics, Hydraulics Safety, Advanced Hydraulics, and now the added training benefit of Troubleshooting capabilities.

The MF102-H-TS includes 40-hours of possible training on the base model PLUS an additional 40-hours of training in troubleshooting possible. Unparalleled in terms of craftsmanship and curriculum, this trainer is proudly designed and built in the USA.

Available Single-Sided or Double-Sided

-

MF102 Hydraulics Trainer with Troubleshooting and Touchscreen

The best hydraulics training system on the market keeps getting better! Fluid Power Training Institute’s MF102-H-TSE Hydraulics Training System with Troubleshooting now includes a built-in Touchscreen Monitor and PC for practical lab activities, troubleshooting, and student tracking!

Students get in-depth, hands-on training in the fundamentals of hydraulics, advanced hydraulics, troubleshooting, safety, and more with over 40 hours of curriculum in the base system, additional 40 hours in troubleshooting, and more with additional options.

With the built-in monitor, instructors can automatically track student activity to determine whether they truly understand how to effectively diagnose hydraulics problems or are just “replacing parts” at random!

Available in single-sided or double-sided systems.

-

Hydrostatic Transmission + Driving Simulator

The MF500-HT-TSE is an instructor’s “dream-come-true” with respect to teaching state-of-the-art, electronically-controlled hydrostatic transmission systems – hands-on. It can even be driven as if it were on a construction site, in real-time!

Driving a skid-steer loader around a construction site and operating the MF500-HT-TSE in the lab amounts to the same thing – without the hazards!

Designed for instructors who want to teach hydrostatic transmission and steering systems with the same components found in popular front-end loaders but without the safety hazards and physical limitations of operating a loaded, faulty skidsteer in a shop full of students.

Teach basic concepts to advanced applications + troubleshooting in a classroom-friendly manner where students can gather around to see real-time symptoms of faults as you drive the simulator through a variety of scenarios.

-

Pump Cavitation Trainer

The FP-MF200-CAV simulator is the most advanced trainer in the world for teaching students everything they need to know about cavitation, its common causes, and its devastating effect on a hydraulic system.

Much thought went into the design of this training masterpiece. The transparent reservoir, transparent pump suction line, and transparent pump outlet port transmission line are backlit to enhance the stunning visual impact this simulator offers.

Students learn:

- How the inlet side of a hydraulic pump works

- Why it is critical to establish a “trend” for pump inlet restriction

- How and why cavitation occurs

- Safe and effective diagnostic procedures for determining the root-cause of cavitation

-

Hydraulic Cylinder Training System

The MF400-HCTS is designed to help instructors teach and students learn how to safely and correctly perform the following skills:

• Overhaul a hydraulic cylinder.

• Identify and use the tools needed to overhaul a hydraulic cylinder.

• Inspect the components in a hydraulic cylinder to determine the root cause of a failure.

• Replace piston and gland seals.

• Test a hydraulic cylinder.

• Air bleed a hydraulic cylinder. -

Industrial / Mobile Accumulator with Differential Pressure Unloading Valve

The MF100-ACC module is an add-on for the MF-102 Hydraulic Training Systems and is designed to help instructors teach and students learn accumulators, accumulator applications, how to safely and correctly perform accumulator gas charging procedures, and applications for differential pressure unloading valves.

The MF100-ACC consists of the following components:

- Accumulator

- Differential pressure unloading valve

- Pressure gauge

- Stored energy safety bleed-off valve

- Gas charging gauge and hose assembly

- Gas bottle pressure regulator recommended

-

Logic Element with Diagnostic Capability

There are some things that no matter how much you try to explain, or how many graphics you use, some students just don’t get it. One of those things has got to be logic valves.

Have you ever asked yourself, “if only I had a fully functional, four logic valve that was completely transparent”? Well, now you do!

Introducing the easy to explain, and just as easy to learn, plug-and-play logic valve module with auto-fault and troubleshooting capability: the MF100-LE-TS. A plug-and-play add-on for the MF-102 Series Hydraulic Training Systems.

-

3-Section Mobile Directional Control Valve

The MF100-MDCV is an actual directional valve assembly that is commonly used on machinery such as front-end loaders and forklifts.

With the MF100-MDCV-TS students will learn to pressure/leak test individual sections with the objective of determining, with pinpoint precision, the condition of a given port.

A plug-and-play add-on for the MF-102 Series Hydraulic Training Systems.

-

Proportional Directional / Flow Control Valve

Combined with the components on the MF102 series training systems, the Proportional Directional/Flow Control Valve Module will allow instructors to teach, and students to learn, all facets of Proportional Directional/Flow Control Valve operation and circuit application, and amplifier parameter adjustment.

The MF100-PDCV module consists of the following components:

- Two-position, 4-way, proportional solenoid controlled closed-center directional/flow control valve.

- Amplifier.

- Joystick controller (linear potentiometer) – optional.

- Aluminum, self-contained unit finished with a durable powder-coat with removable steel back cover.

- Front-plate with printed identification symbols and color-coding.

- Appropriate warnings and cautions.

-

Industrial / Mobile Directional Control Valve

The MF100-SVM is the actual stacked valve assembly that is commonly used in hydraulic systems on modern production, manufacturing and mobile machinery.

The MF100-SVM consists of the following components:

- Directional control valve, 03 size, three-position, four-way, solenoid-operated,

spring-centered, with float-center. - Sub-plate with quick connect/disconnect valves.

- Circuit module 1 – Main pressure relief valve, adjustable.

- Circuit module 2 – Cylinder port relief valve, adjustable.

- Circuit module 3 – Dual, flow control valves, adjustable.

- Circuit module 4 – Dual, pilot-operated (pilot-to-close) check valves.

- Directional control valve, 03 size, three-position, four-way, solenoid-operated,